Scaling an e-commerce business is tough when operations are spread across fragmented tools. Listings, orders, inventory, customer communication, invoices, and integrations often sit in separate systems, creating confusion and inefficiencies. Add to this the complexity of managing marketplaces, B2B partners, your own online store, and offline channels, and it can feel like juggling disconnected pieces without a single source of truth. What if every part of your operation could be brought together into one seamless system?

That’s where Base.com comes in, offering a centralized, automated, and customizable platform to help you scale. Whether you sell through marketplaces, your own online store, B2B channels, or offline retail, Base.com offers a centralized, automated, and customizable order and product management experience that helps you scale without chaos.

This guide outlines how Base.com allows businesses to scale effortlessly by consolidating operations under one powerful platform – eliminating the need for five different tools that don’t communicate.

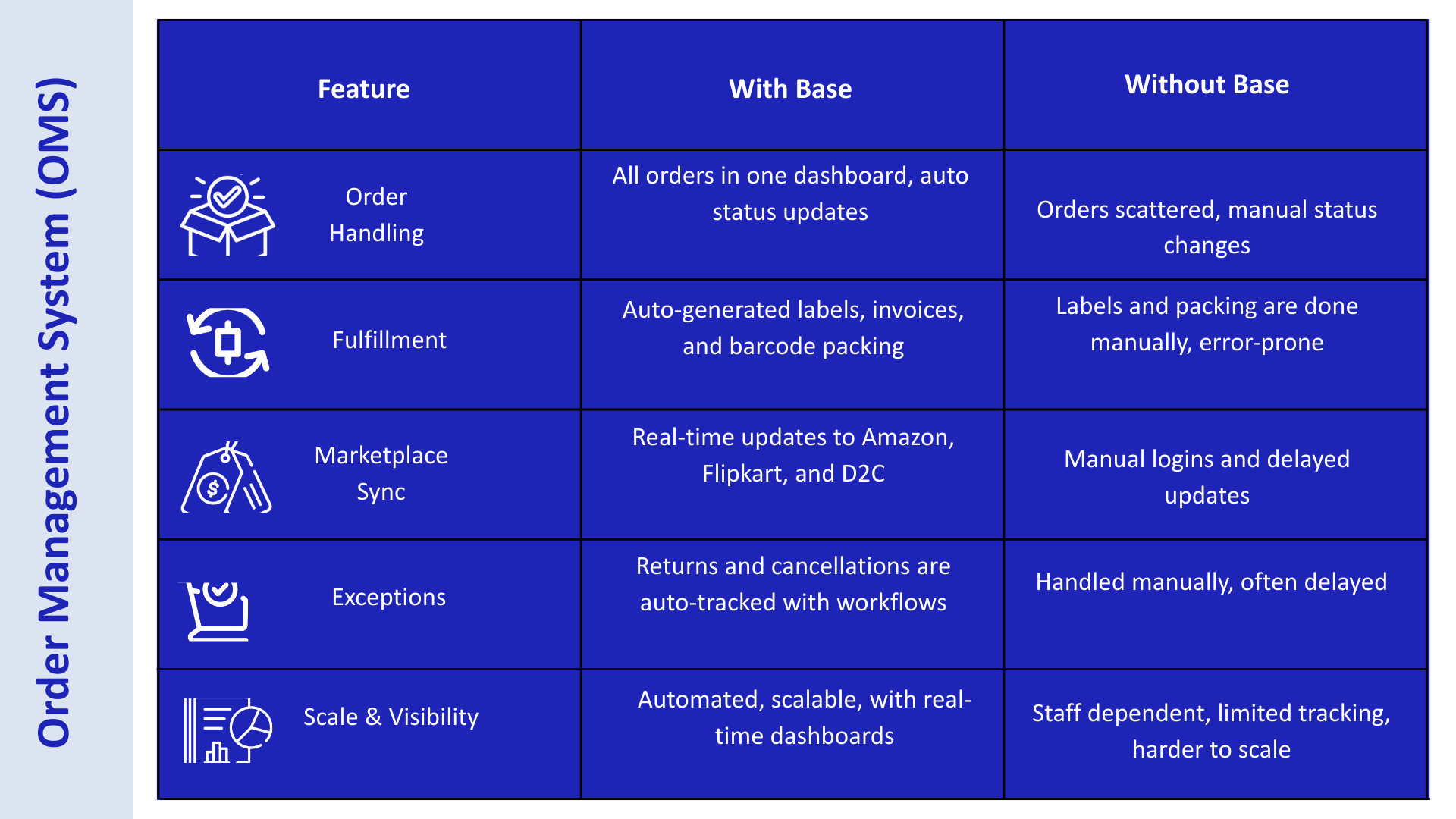

1. Centralized Order Management System

Now-a-days, in e-commerce, businesses are selling across multiple channels such as Amazon, Flipkart, Myntra, and their own direct-to-consumer (D2C) websites. Managing fulfillment across these platforms without a centralized system leads to several challenges, including delayed dispatches, missed pickups, SLA violations, manual reconciliation, and poor visibility across teams.

Base solves this by offering a single, centralized Order List system with built-in automation, customizable views, channel-specific workflows, and real-time data sync. It empowers teams to handle every order, from placement to delivery, with zero manual touch and full operational clarity.

A. Why do businesses need a centralized order management system?

The centralized Order List in Base is a consolidated dashboard that acts as the source of truth for all your orders, regardless of the platform or warehouse from which they originate. Every order, whether from Amazon, Flipkart, Myntra, or your own online store, flows into this dashboard automatically via Base’s integrated APIs.

Key capabilities include:

- Real-time visibility into all order stages

- Full customization to group or filter orders by status, channel, region, or priority

- Automated workflow execution at every step of the order journey

- Smart management of cancellations, returns, and channel-specific SLAs

- Direct communication with marketplaces and logistics partners

This system brings structure and automation to your entire order fulfillment process.

B. How does the order lifecycle flow in Base?

Base takes a customized, structured approach to order management. Unlike rigid one-size-fits-all systems, every business operates differently, and Base adapts to those workflows by mapping each order through configurable, predefined stages.

This ensures complete visibility, consistency, and control across the order lifecycle. Whether you need a simple flow for D2C or a complex multi-step process for B2B and offline distribution, Base’s structured approach eliminates errors, reduces manual intervention, and guarantees that no order slips through the cracks.

- Order Fetch – As soon as an order is placed on any marketplace or D2C site, Base.com fetches it into the system via API. Sellers can configure how often orders sync, which channels to prioritize, and apply rules for automatic tagging.

- Shipment Creation, Marketplace Confirmation & Cancellations – Base supports fully customizable order flows tailored to each brand’s warehouse operations. For example, a shipment can be created instantly and confirmed back to the marketplace. This process can automatically generate shipping labels, assign couriers, and trigger marketplace-specific SLAs. Cancellations are managed by removing canceled orders from the workflow or notifying warehouse teams before packing begins. All of these behaviors are optional, rule driven, and configurable per channel, order type, or location.

- Warehouse Operations – The order moves into warehouse workflows where picking, packing, labeling, and manifest generation are completed. Sellers can configure custom picking rules, packing priorities, barcode scanning requirements, and exception handling.

- Courier Handover – Once packed, the order is handed over to the courier with real-time tracking synced. This can be configured to select courier partners dynamically, set handover cutoffs, or update marketplaces automatically with tracking details.

Every transition above is automated using Base’s no-code rules engine. The system updates all statuses and communicates with the necessary stakeholders without human intervention.

C. How do you automate order processing in Base?

The most powerful aspect of Base’s Order List is its automation engine. It lets you automate your entire warehouse workflow using triggers and events. These are called automatic actions. You can set them up based on your marketplace, like Amazon, Flipkart, or others. Each platform has its own process, and Base allows you to follow those exactly without doing things manually. With preconfigured business rules, you can build end-to-end fulfillment flows without needing to code or involve developers.

Common examples include:

- Tagging and prioritizing new orders based on channel or product category

- Automatically scheduling shipments based on dispatch deadlines or warehouse slot availability

- Printing shipping labels and manifests upon reaching the “Ready to Dispatch” stage

- Moving orders to “In Transit” once pickup is logged by the courier

- Receiving and processing delivery confirmations from the marketplace

- Triggering RTV processes automatically upon cancellation after shipping

All actions are traceable in Base’s audit logs, and teams can rely on the system to execute fulfillment operations around the clock.

Base replicates marketplace-specific fulfillment flows by automating order tagging, packaging, and label generation based on shipping timelines. For platforms like Amazon, Flipkart, it mirrors their dispatch logic and status updates to ensure timely, compliant operations without manual effort.

In short, automatic actions in Base help you run operations smoothly without manual work. You can set up custom rules for each channel to match how Amazon, Flipkart, Myntra, or your own warehouse works. Once set, Base takes care of the rest.

D. How are cancellations and returns handled in Base?

Base intelligently manages both pre-shipment cancellations and post-shipment returns (RTVs). These are two separate workflows that the platform automates completely:

- Customer or Marketplace Cancellations: When a customer cancels their order on Amazon or Flipkart, Base detects it via API and removes it from the fulfillment queue. It can also alert warehouse teams to hold packing if the cancellation is detected late.

- Post-Dispatch RTVs: When an order is returned after shipment, Base initiates RTV tracking. It monitors reverse pickup confirmation, courier updates, product quality check status, and triggers notifications to finance or inventory teams for restocking or reconciliation.

All such exceptions are visible in the dashboard under dedicated cancellation and RTV views.

E. How does invoicing work in Base.com?

Base.com provides a complete invoicing solution that helps businesses create, manage, and distribute invoices and related documents efficiently across all order sources. Whether you’re selling on Amazon, Flipkart, your own online store, or processing wholesale orders, Base.com supports manual and automatic invoicing flows to simplify financial documentation and reduce operational overhead.

Base.com supports four types of invoices: Standard Invoice, Receipts, Correction Invoice, and Pro Forma Invoice. For D2C platforms like Shopify, these can be generated manually for individual orders or triggered automatically as part of the order processing workflow.

For marketplaces in India, invoices are not created by external systems like Base; instead, they are pulled directly from the marketplace and made available in Base to download and print.

- Manual Invoicing: From the Order List, users can select one or multiple orders and generate the required invoice type. Each invoice can be edited or deleted before confirmation. Corrections can also be made by selecting an existing invoice and applying changes such as date adjustments, pricing changes, or adding/removing items.

- Automatic Invoicing: Businesses can configure automatic actions to issue invoices based on triggers such as order status changes (e.g., when an order is marked as “Packed” or “Shipped”). This helps reduce delays in documentation and ensures all financial records are up to date without manual work.

- Template Customization: Users can customize invoice templates using HTML. These templates can include custom tags for dynamic data like product SKUs, buyer details, tax values, discounts, and barcodes. The layout, page size, numbering format, and inclusion of company branding elements like logos and footers can all be customized.

Base.com provides a consolidated invoicing solution that adapts to various business models and compliance needs. It ensures marketplace compliance by automatically generating and attaching invoices at dispatch for platforms like Amazon and Flipkart.

For GST-registered Indian sellers, it creates fully compliant invoices with HSN codes, tax breakdowns, and export formats compatible with tools like QuickBooks and Zoho. D2C brands and wholesale sellers can issue branded Pro Forma or Standard invoices, either manually or through automation, and share them via email, SMS, or embedded customer info pages.

This streamlined approach minimizes manual effort, enhances accuracy, and ensures end-to-end financial traceability.

Base transforms order management into a fully automated, streamlined system. Without it, operations are slow, manual, and harder to scale.

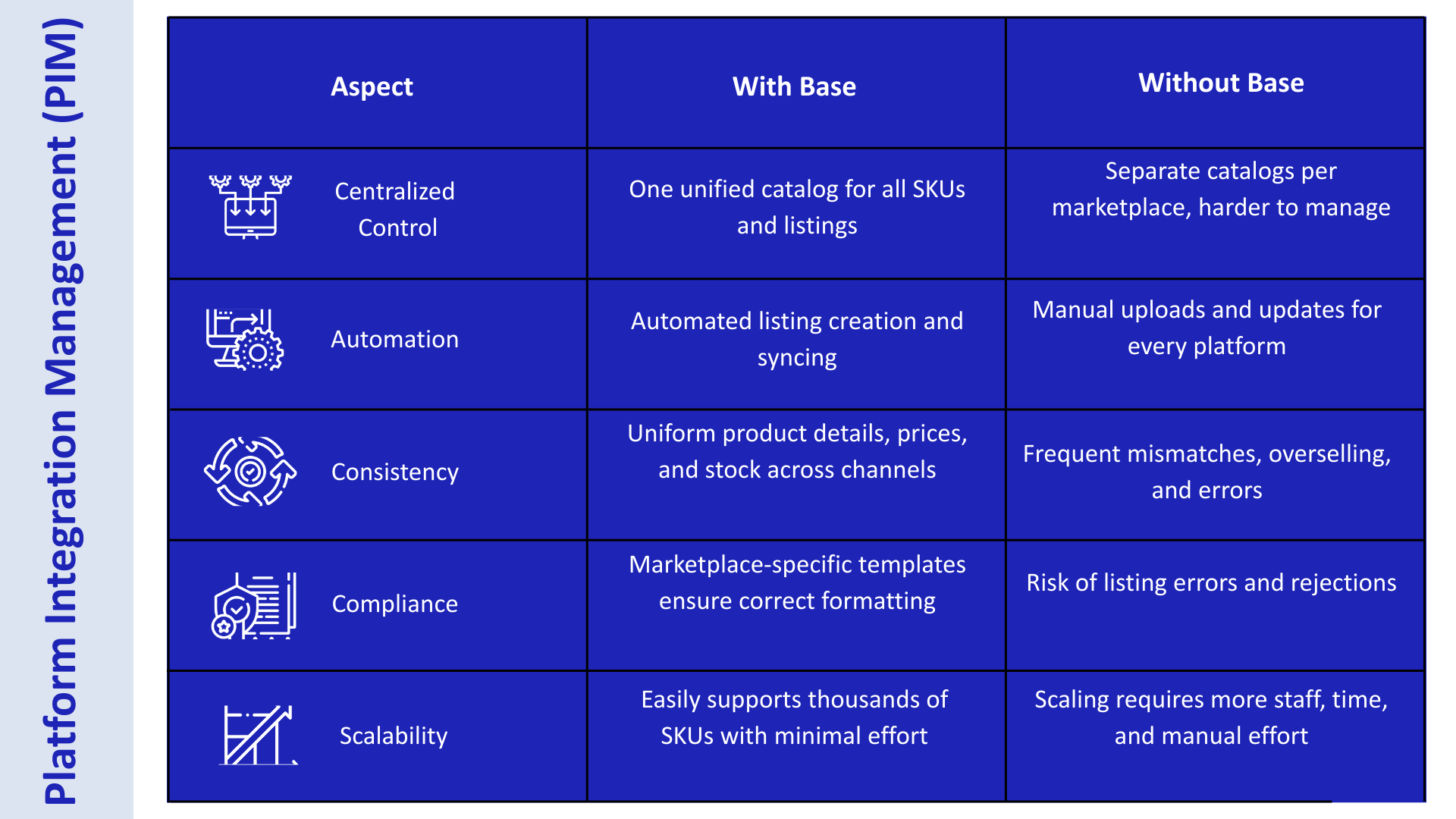

2. Product Information Management (PIM)

Managing product data across multiple sales channels like Amazon, Flipkart, Shopify, and WooCommerce is complex and time-consuming. Each platform has different requirements for SKUs, titles, taxes, categories, and stock sync. Without a centralized system, sellers often face mismatched listings, overselling, and poor time-to-market for new products.

Base.com solves this with a centralized Product Information Management (PIM), also known as Catalog Management system that brings together catalog control, automated listing creation, real-time stock and price synchronization, and marketplace-specific template management. Sellers no longer have to manage separate listings on each channel. Instead, they maintain one unified product record and let Base handle the logic for how it appears and behaves on each marketplace.

A. How Does Base.com’s Integration Ecosystem Work?

Base.com provides access to over 1500 prebuilt integrations, enabling seamless connectivity across various parts of the e-commerce ecosystem.

With support for both domestic and global channels, Base acts as a single system to manage marketplaces, stores, logistics providers, ERPs, and payment gateways worldwide, eliminating the need for multiple disjointed tools. These include:

- Marketplaces (Amazon, Flipkart, eBay, etc.)

- Online Shops (Shopify, WooCommerce, Magento, and more)

- Courier Services (Delhivery, Blue Dart, FedEx, and others)

- Third-party Fulfillment Providers (3PL warehouses)

- Accounting and ERP systems (Tally, QuickBooks, Zoho, etc.)

- SMS Gateways and Wholesalers

Sellers can connect these services independently by going to the Integrations tab and clicking Add Integration. Each platform may have its own setup steps and authorization flow, so Base.com provides channel-specific user guides to support the configuration. Once integrated, the seller can control data synchronization (orders, products, inventory, and statuses) through configurable parameters.

Sellers can choose how frequently orders are imported from connected channels, such as every 10 minutes or every 1 minute for near real time updates. Once fetched, orders are automatically assigned a preferred status like Pending or Awaiting Payment.

Sellers can also override the product name, SKU, thumbnail, and tax rate with values from their Base.com catalog to ensure consistency. Orders can be forwarded to webstores like Shopify for centralized processing, and tracking details can be sent back to the original channel. These settings help unify multichannel order management, reduce manual work, and improve accuracy.

Shipment integration in Base.com automates the logistics process by connecting your system with courier partners. It auto-generates shipping labels, assigns tracking numbers, and updates marketplaces or customers without manual input. Sellers can configure package dimensions, label formats, and dispatch rules for each courier. Tracking info is synced back to channels to meet SLA requirements. This streamlines fulfillment, reduces errors, and speeds up delivery operations.

By offering such flexible integration and configuration options, Base.com helps sellers:

- Avoid manual order and stock updates across platforms

- Maintain consistency across marketplace listings, catalog data, and financial systems

- Meet platform-specific requirements (like Flipkart’s SLA for tracking updates)

- Consolidate all D2C and marketplace operations into a single order processing workflow

This flexibility makes Base.com not just a connector, but a powerful orchestration layer for modern multi-channel e-commerce.

B. How Does Base.com Simplify Listing Management Across Marketplaces?

Base.com enables sellers to consolidate and manage product listings from multiple marketplaces and webshops in one place. This streamlines catalog management, reduces manual errors, and improves listing accuracy across channels like Amazon, Flipkart, Shopify, and more.

- Bulk Listing Import: Easily import all listings from connected marketplaces and online shops, including parameters like:

- SKU ID

- ASIN

- Quantity

- Price

- EAN

- Current and expired offers

- Centralized Catalogue Mapping: Base allows you to map different SKUs from different marketplaces to one master SKU. This:

- Prevents duplication

- Maintains inventory accuracy

- Ensures consistent updates across all platforms

- Cross-Channel Listing Sync: Product edits (like price changes or stock updates) made in Base can be reflected across all integrated sales channels, keeping everything synchronized in real-time.

- Multi-Platform Monitoring: Track listing status, stock availability, and promotions for each product across multiple marketplaces from a single dashboard.

Each platform has different requirements for catalogues, pricing, and offers, making it easy to lose control and introduce errors. Base.com’s listing management module provides a single source of truth, allowing you to centralize, map, and monitor all listings from one place.

C. How Does the Listing Creator Automate Product Publishing?

The Listing Creator module in Base.com simplifies the process of publishing products to marketplaces like Amazon, Flipkart, or eBay. Instead of manually filling out submission forms for each new product, sellers can rely on Base.com’s automation to create listings directly from their central catalog.

- Automatic Offer Creation: Your selected storage or catalog automatically lists products on Amazon and other marketplaces. Each new product converts into an active offer without requiring you to fill out marketplace submission forms.

- Condition-Based Display: You can set conditions that determine which products appear. For example, the system can automatically list only products with stock above zero or those assigned to a specific category.

- Duplicate Prevention: If a product already exists in the marketplace catalog, Base.com detects it and prevents duplication. This ensures clean listings and avoids penalties for multiple entries.

- Automated Cycles: The system runs checks every few hours to find products that meet the defined conditions. Up to 100 new products can be listed in one cycle, with further offers added in subsequent cycles.

- Marketplace-Specific Templates: Using Base’s central product library, sellers can create custom templates tailored to marketplace requirements. Templates cover parameters like product titles, descriptions, pricing rules, tax classes, shipping methods, and attributes. This ensures that each marketplace listing follows its own rules while still being controlled centrally.

The Listing Creator in Base.com automates publishing products across marketplaces directly from your catalog. It eliminates repetitive manual uploads while ensuring accuracy and compliance.

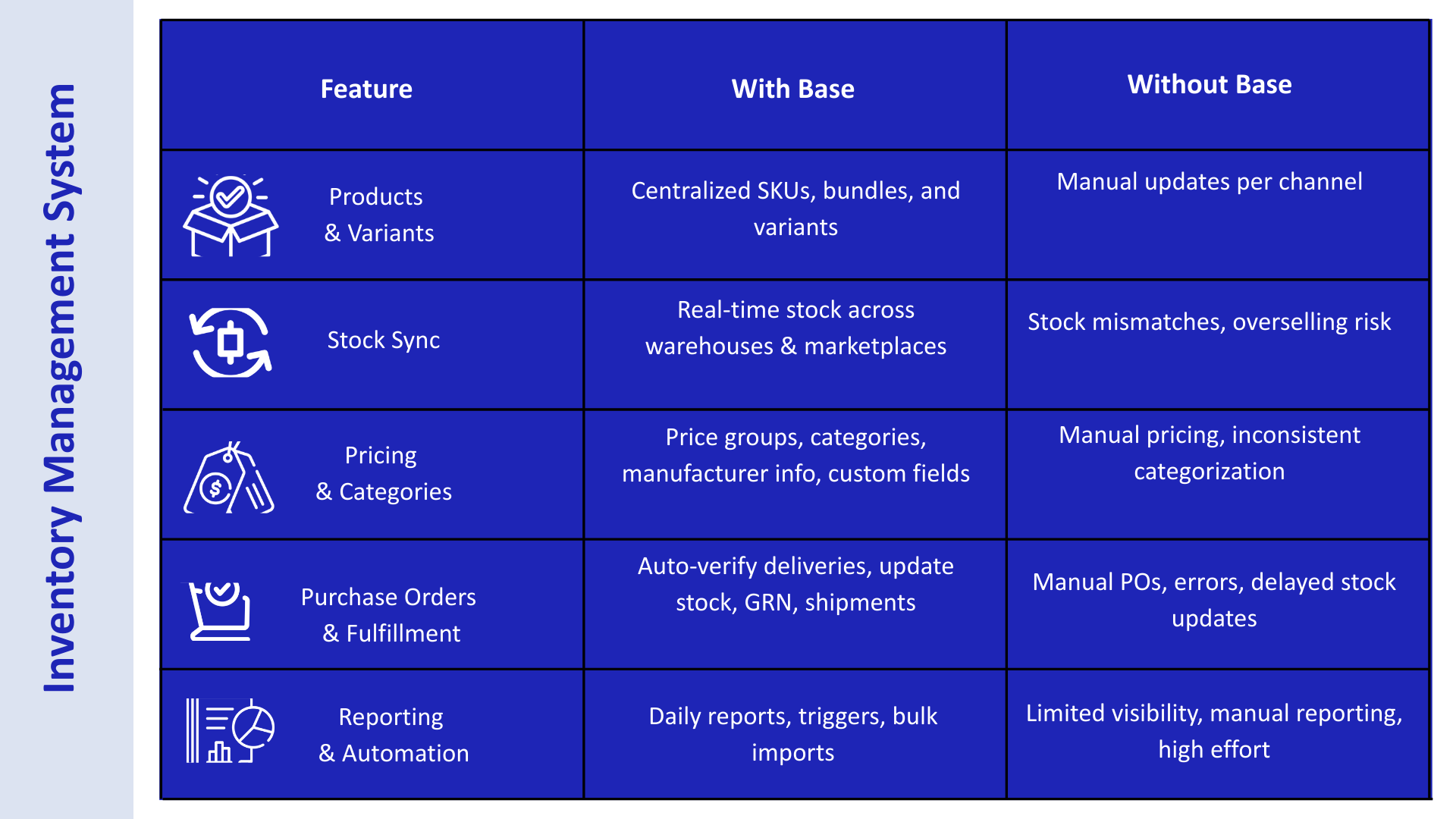

3. Inventory Management System (IMS)

Managing inventory across multiple warehouses, marketplaces, and sales channels can quickly become complex. Without a proper system, sellers face stock mismatches, delays in replenishment, and difficulty scaling operations. The Inventory Management System (IMS) within Base helps sellers centralize all product, warehouse, and stock-related operations while enabling automation, reporting, and real-time synchronization.

A. How Does Base.com Manage Product Lists and Variants?

A seller running three marketplaces and two D2C stores can automatically reflect low-stock updates across all channels, preventing overselling.

The Base system gives sellers a product card view where each product can store essential attributes like name, description, tags, dimensions (length, breadth, height), and category.

Sellers can easily manage multiple product variations such as size and color, while also creating bundles like a shampoo and conditioner combo linked to individual SKUs. A unified sales and warehouse view allows them to track tax, pricing, stock thresholds, goods in transit, and warehouse allocations, providing complete visibility into inventory levels and locations.

Bulk operations further streamline tasks by enabling quick price updates, stock corrections, bundle creation, or product deletions without the need for individual edits. Centralized publishing pushes product descriptions, parameters, and images directly to connected marketplaces, maintaining consistency across all channels.

B. How Does Warehouse Synchronization Work in Base.com?

A seller with warehouses in Delhi and Mumbai can allocate specific stock pools to different marketplaces. The system fulfills orders from the nearest warehouse based on the customer’s location, reducing delivery times and improving efficiency.

IMS allows sellers to create multiple inventories and warehouses depending on their business needs.

- Multi-Inventory: Useful for separating product pools if a seller operates multiple stores with different assortments.

- Warehouse Allocation: You can connect a single warehouse to multiple inventories. Sellers can also create sub-storages to represent separate physical or logical stock (e.g., damaged goods, returned goods, or external storage).

- Synchronization: Parent warehouses push stock to channels, while sub-storages pull stock from external systems. Both directions can be active at once, ensuring real-time availability.

- Warehouse Division: You can break storage down into racks, zones, and containers (such as pallets and boxes) to make picking and packing more efficient.

C. How Are Pricing and Categorization Handled in Base.com?

Base helps sellers manage how products are priced and categorized across different sales channels. It allows the creation of price groups to maintain separate price lists for various marketplaces, currencies, or customer groups, with the option to either push updates to channels or pull them from external stores.

Base.com lets you adjust pricing per channel. For example, you can lower prices on Amazon during a sale while keeping Shopify and Myntra prices unchanged.

D. How Does Base.com Manage Inventory Control and Purchase Orders?

A seller restocking 500 units of headphones from a supplier can generate a PO, track the goods in transit, and once received, auto-update stock across all connected channels.

The system enables strict control of stock movement with detailed purchase order and stock document management.

- Purchase Orders (POs): Sellers can create and send purchase orders to suppliers directly from the system. When deliveries arrive, the software automatically verifies the delivered quantities against the PO and updates inventory levels in real time. This reduces manual errors and ensures that stock records remain accurate.

- Documents (GRN, Stocktakes, Draft States): The system supports essential inventory documents such as Goods Receipt Notes (GRNs) for confirming received items, stocktakes for periodic inventory audits, and draft-to-completion workflows for purchase orders. This ensures transparency and accuracy across all procurement and stock management stages.

- Fulfillment Shipments: Sellers can pack products into cartons or pallets and arrange shipments to external fulfillment centers such as Amazon FBA. The platform automatically syncs these shipment details, keeping both sellers and fulfillment centers aligned. This eliminates manual updates and ensures that fulfillment records stay consistent.

- Lean Inventory Practice: The software is designed with lean inventory principles. It includes built-in checks to help sellers prevent overstocking or understocking, which can lead to unnecessary costs or missed sales. By maintaining the right balance, sellers optimize cash flow and ensure smoother order fulfillment.

E. How can sellers automate their stock replenishment?

A seller can automate a trigger that whenever stock drops below threshold, the system auto-generates a draft PO to reorder from the supplier, reducing the risk of stock-outs. IMS provides actionable insights and automation features.

The system provides daily reports that track inward and outward warehouse values, giving sellers clear financial visibility and helping monitor stock movement. Automated triggers assign a supplier as soon as you create a new product, reducing manual effort and ensuring consistency. You can also bulk-import products from multiple sources—including ERP systems, FTP servers, online shops, and marketplaces—to streamline catalog updates and save significant time.

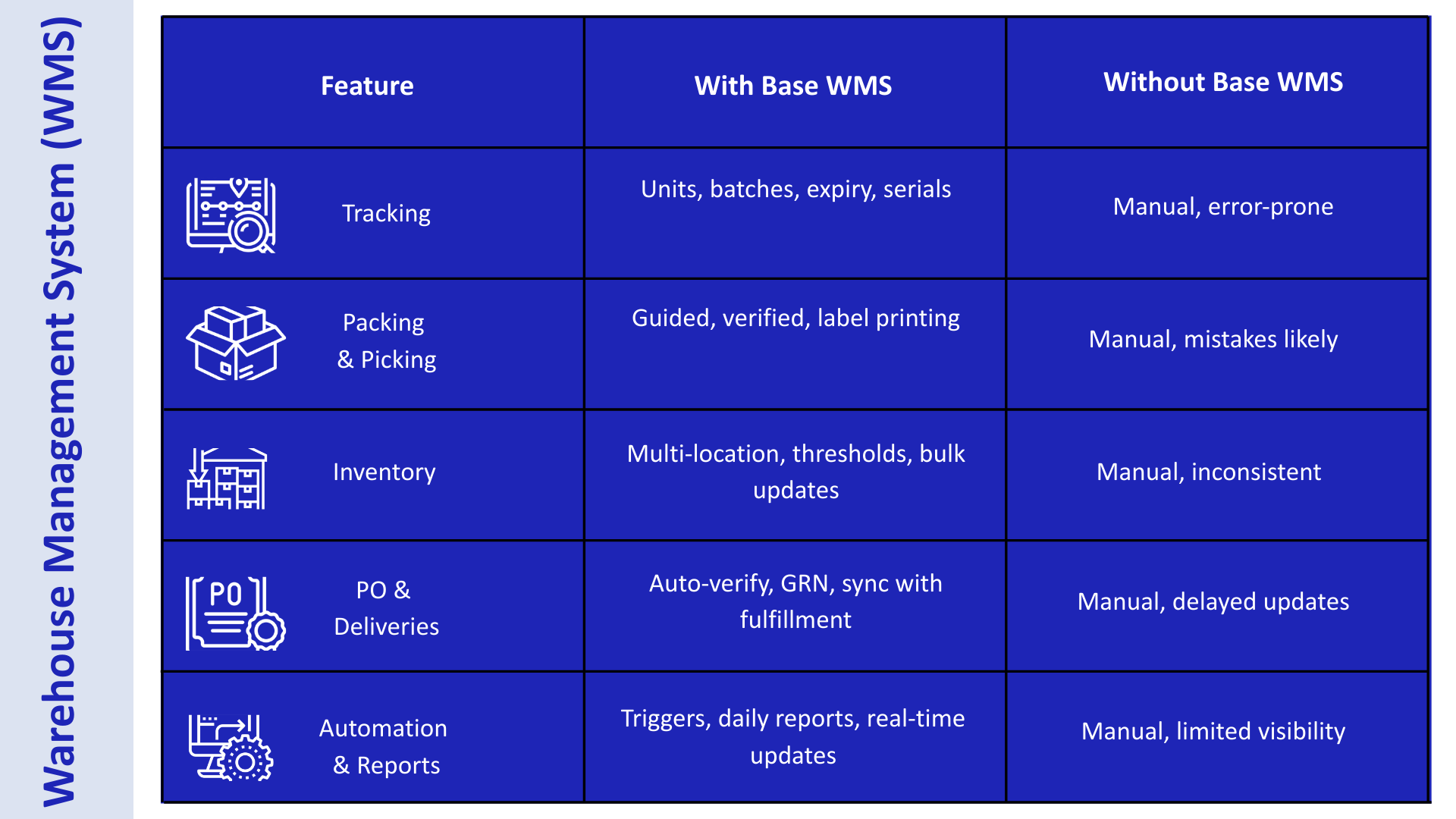

4. Warehouse Management System

Base.com provides a comprehensive Warehouse Management System designed to make warehouse operations simpler, optimize stock control, and enhance order fulfillment. Each feature directly tackles the everyday challenges sellers face, improving efficiency, accuracy, and scalability.

A. How Does Base.com Track Products by Unit and Location?

Sellers handling perishable goods like food or cosmetics, or serialized items like electronics, often struggle to pick and ship the correct products. Without a system to track batches, expiration dates, or serial numbers, it is easy to accidentally send expired or wrong items.

Managing stock across multiple warehouses adds complexity, making it difficult to locate inventory quickly, monitor product lifecycles, and maintain accurate records of product variants. These challenges can lead to increased returns, customer complaints, and lost revenue.

Base.com allows tracking of each product unit individually, including batch numbers, serial numbers, and expiration dates. Sellers can assign products to multiple warehouse locations and even split stock according to specific conditions, such as expiry or batch.

Manual stock tracking often leads to errors, such as shipping expired products, misplacing inventory, or duplicating serial numbers. Base.com eliminates these issues by providing real-time visibility of each product unit across all locations, ensuring accuracy and compliance.

B. How Does Base.com Automate Order Picking and Packing?

Sellers managing high order volumes or multiple SKUs often struggle with picking and packing accurately. Manual processes can lead to shipping expired items, sending wrong quantities, or delays when handling multiple orders. These errors increase costs and hurt customer satisfaction.

How Base.com Helps

- Customizable pick lists and pack lists: Users can design these documents in any format they prefer, adding fields such as location, batch, expiry date, barcodes, or order notes to match their warehouse process.

- Guided picking with clear instructions on location, batch, and expiry dates, fully adaptable to brand-specific workflows.

- Packing assistant that verifies items during packing, ensuring correct product, quantity, and sequence as per the customized pack list.

- Automated label printing lets you tailor formats and layouts to couriers, marketplaces, or your internal standards.

- Multi-order processing using location and batch-based rules defined by the user.

- It integrates with WMS units to track batch, serial number, and expiry data individually, and reflects all of this information in pick/pack documents.

- Barcode scanning to automate picking and packing, usable with Base scanners or a mobile camera via the Base app.

By putting customization at the core, Base.com adapts to each seller’s unique warehouse operations. Instead of forcing rigid workflows, it lets businesses design the way they pick, pack, and ship; reducing errors, saving time, and ensuring accurate, efficient fulfillment at scale.

C. How Does Base.com Simplify Procurement?

Sellers managing deliveries from multiple suppliers often struggle with manual stock updates, verification of received products, and assigning them to the correct warehouse locations. Errors in this process can lead to stock discrepancies, missed deadlines, and inefficient warehouse operations.

How Base.com Helps:

- Multiple Input Methods: You can add delivery products manually, through automatic rules, by importing a CSV, or soon via API integration.

- Automated Stock Management: The system can create new deliveries, balance stock, and order products based on fixed quantities, sales trends, or defined periods.

- Supplier Communication: You can send orders to suppliers in CSV or PDF formats or through a dedicated supplier portal, with tracking included.

- Verification and Scanning: Delivered products are verified via barcode or QR code scanning, ensuring accurate receipt.

- Real-Time Stock Updates: The WMS receives reception data instantly and automatically updates stock after confirmation.

- Location Assignment: You can assign products to locations manually or automatically based on criteria like expiration date, weight, sales volume, or dimensions.

- Advanced WMS Features: Each delivery item can include expiration date, batch number, serial number, and storage location for precise tracking.

- Documentation: Accepting a delivery generates a GRN document, with options to add additional costs, tracking numbers, or notes.

Why Base.com is the Only Tool You Need?

Why Base.com is the Only Tool You Need?

Scaling an e-commerce business doesn’t require juggling multiple tools for orders, inventory, warehouses, marketplaces, shipments, and invoices. Base.com brings all these operations into one unified, automated platform.

With Base.com, sellers gain real-time stock synchronization, guided warehouse operations, automated purchase orders, seamless marketplace integration, and centralized reporting. This eliminates errors, prevents overselling, reduces manual work, and saves valuable time.

Instead of mapping and reconciling several tools, Base.com handles everything accurately and efficiently. It simplifies workflows, improves operational visibility, and supports growth at scale.

Base.com is the complete solution to manage, automate, and scale your e-commerce business.

Frequently Asked Questions

1. Can Base.com help me manage pre-orders or out-of-stock products?

2. How does Base.com handle different tax rules for international shipment orders?

Base.com supports multi-region tax configurations, allowing sellers to apply GST, VAT, or custom rules by country. The system automatically calculates taxes on invoices, syncs them with your accounting software, and keeps them compliant for both domestic and export orders. The platform also supports global shipment terms like FOB and CIF, giving sellers flexibility in handling international trade. Together, these features simplify cross-border selling and ensure smooth financial operations.

3. Can Base.com customize order workflows to match my warehouse operations?

Absolutely. Base.com is built for customization, letting you design order flows that truly match how your business operates. You can set custom stages, rules, and triggers for D2C, B2B, or offline orders, ensuring processes reflect your warehouse reality. Beyond automation, Base connects picking, packing, invoicing, shipping, and reporting into one seamless system, delivering not just automated tasks but a fully orchestrated system tailored to you.