For Indian eCommerce sellers, whether you are selling on Amazon, Flipkart, Meesho, JioMart, or your own Shopify or WooCommerce store, one of the biggest threats to your profit margin is operational error, especially during the picking and packing stage of order fulfillment. These mistakes may seem small, but they have a compounding impact on your bottom line.

Most sellers invest heavily in marketing, product sourcing, and platform optimization but overlook basic warehouse processes. A mispicked item, wrong quantity, or missed product in a package can cost between ₹200 to ₹600 per order when you account for reverse shipping, customer service, repacking, and reshipping. This does not include the damage to your seller ratings, the increase in returns, or the potential loss of repeat customers.

Consider a typical mid-sized seller dispatching 300 orders a day. Even a 1.5 percent error rate results in 4 to 5 incorrect shipments daily. That is a loss of ₹60,000 to ₹90,000 per month just in operational wastage, not counting lost goodwill. Over time, these silent losses eat into margins, slow growth, and in many cases cause sellers to burn out or shut down without ever identifying the real cause.

Why Picking and Packing Errors Happen in eCommerce Fulfillment

In a typical eCommerce warehouse, once an order is placed, the warehouse team initiates two key operations. The first is picking, where staff members locate the right products from storage shelves. The second is packing, where the picked items are boxed, sealed, labeled, and made ready for shipment. While these may sound simple, the pressure of high volumes, untrained labor, manual processes, and poor inventory visibility makes these steps highly prone to mistakes.

Picking errors occur when warehouse staff select the wrong item, the wrong variation such as size or color, the wrong quantity, or fail to pick an item at all. These errors are often caused by lookalike products, poorly organized shelves, or lack of barcode systems.

Packing errors usually involve sending the wrong combination of items, using the wrong box size, forgetting to include fragile protection for sensitive products, or missing an item in a multi item order. This usually results from rushed operations, lack of checklists, and no final quality control stage.

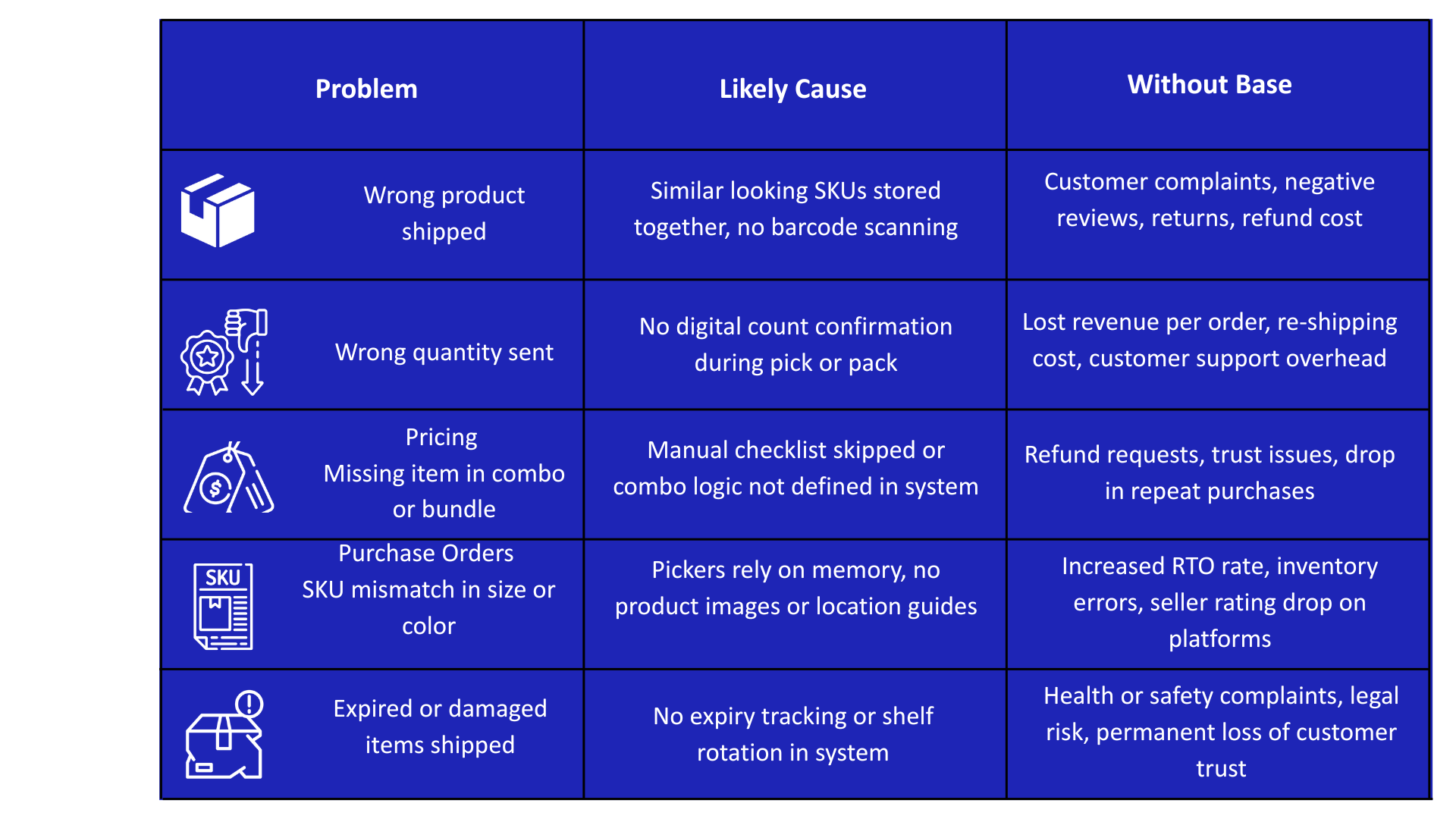

These issues not only delay delivery but also increase return rates, raise shipping costs, and reduce customer satisfaction. Here is a detailed table showing the types of picking and packing errors along with real use cases from common eCommerce industries in India:

Real Use Cases of Picking and Packing Errors Across Industries

In many of these cases, the root causes are the same. Warehouses that do not use barcode scanning, rely heavily on manual processes, or skip quality checks are far more likely to face repeat errors. Fixing these issues is not just about accuracy but about protecting brand reputation, reducing returns, and maintaining healthy profit margins.

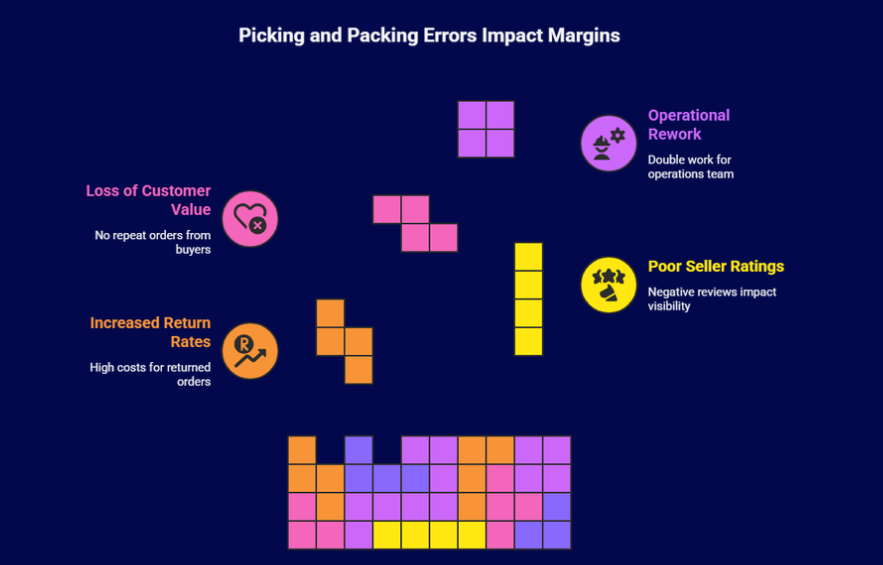

How Picking and Packing Errors Impact Your Margins

Mistakes made in your warehouse do not just lead to returns. They trigger a ripple effect across your entire operation, from rising logistics costs to loss of customer loyalty. Below are the four biggest ways picking and packing errors eat into your profits, with real world examples relevant to Indian ecommerce sellers.

1. Increased Return to Origin (RTO) Rates

In India, the cost of a returned order is often more than the cost of a successful delivery. This is due to double handling, reverse courier charges, and repackaging. A customer who receives the wrong item is far more likely to reject it at delivery or initiate a return shortly after. For example, if you send the wrong phone case on a prepaid order, the buyer may file for a return, and you will not only pay for reverse shipping but also lose the original shipping cost and customer trust. In cash on delivery cases, the customer might simply refuse delivery, and you bear the full cost of logistics both ways.

Over time, these RTOs reduce your profit margin per order. If you ship 500 orders a day and 2 percent get returned due to fulfillment mistakes, you are losing tens of thousands of rupees each month in avoidable costs.

2. Poor Seller Ratings and Platform Penalties

Marketplaces like Amazon, Flipkart, Meesho, and JioMart use strict performance metrics to evaluate seller quality. If your packing team sends the wrong variation of a product, for instance a blue shirt instead of a black one, the customer may leave a negative review even if you resolve the issue later. A single one star or two star review can drop your overall rating, which affects your visibility on search pages.

More importantly, marketplaces can suspend your Buy Box eligibility or delay your payments if error rates go above their acceptable threshold. This makes it harder for you to win new orders, even if your products are competitively priced.

3. Loss of Customer Lifetime Value

This is especially critical for direct to consumer brands. Unlike marketplaces where the customer relationship is controlled by the platform, DTC brands rely on repeat orders and long term trust. If a first time buyer receives an incorrect order, for example a skincare combo missing one item, they are unlikely to return.

Customer acquisition is expensive. You may spend ₹100 to ₹300 or more to acquire a new buyer through ads or influencer marketing. Losing that buyer due to a fulfillment error not only wastes that cost but also eliminates any chance of recovering the investment through repeat purchases.

4. Operational Rework and Time Drain

Every picking and packing mistake leads to double the work for your operations team. If a wrong item is shipped, someone must receive the complaint, verify the issue, approve the return, restock the product, and prepare a replacement. This rework takes time and adds workload for your warehouse, support staff, and accounting team.

For example, a seller handling 200 daily orders with a 2 percent error rate will have to deal with four such incidents daily. That translates to 120 unnecessary customer interactions and 120 replacement shipments in a month. These delays hurt productivity and slow down other orders. Over time, this reduces your operational efficiency and requires additional staffing, which increases fixed costs.

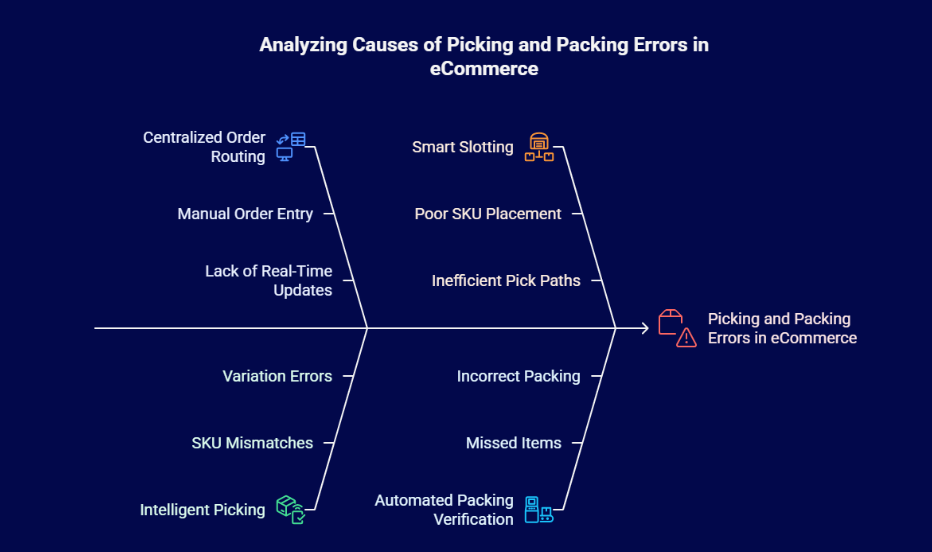

Root Causes: Why These Errors Happen in eCommerce Warehouses

Most eCommerce sellers in India, especially small to mid sized businesses, rely heavily on manual fulfillment processes. In many warehouses, there is no barcode system in place. Pickers are expected to identify products based on memory, printed pick lists, or visual inspection. This becomes a serious problem when products look alike, such as two flavors of the same snack, different colors of the same T-shirt, or similar mobile chargers. When these products are stored close together without proper labeling or scanning systems, the risk of picking the wrong item increases significantly.

Packing errors are just as common. Without a system in place for verification, it is easy for a packer to miss one item in a multi product order or place the wrong variation of a product in the box. In warehouses that process hundreds of orders per day, even a small mistake rate results in significant costs. These mistakes are often made worse by the absence of a final quality control step, where packed items are supposed to be scanned and cross checked before shipping. Poor lighting, unclear shelving layouts, and untrained staff further contribute to mistakes that seem small but add up quickly.

What makes these problems even more damaging is the lack of visibility and accountability. When there is no tracking of who picked or packed a specific order, sellers are unable to find patterns or take corrective action. Over time, this leads to inventory mismatches, increased return rates, customer dissatisfaction, and damage to the brand’s reputation. These are not rare exceptions, they are daily realities for many businesses operating without automation.

Common Picking and Packing Errors: Causes and Consequences

How Automation Fixes Picking and Packing Errors in eCommerce Fulfillment?

Automation is no longer optional for Indian eCommerce sellers looking to scale beyond a few hundred orders a day. The transition from manual to automated fulfillment not only improves accuracy but also unlocks speed, efficiency, and real time visibility across your entire order lifecycle.

Let us explore how automation directly eliminates the most common causes of picking and packing errors and where its real value lies.

1. Centralized Order Routing and Control

One of the biggest issues in multichannel selling is managing orders from different platforms like Amazon, Flipkart, Meesho, Shopify, or your own website in one place. Without a centralized interface, orders must be manually entered into your system, increasing the risk of entry errors, missed updates, or incorrect product mapping.

An automation platform allows all these orders to sync into one dashboard. From here, pick lists are generated automatically, shipping labels are matched to the order, and inventory is updated across platforms in real time. This eliminates duplicated work and prevents picking the wrong SKU due to outdated or disconnected systems.

2. Intelligent Picking Using Barcode Scanning

Automated systems create dynamic pick lists sorted by zone, frequency, or priority. Each item on the list is linked to a barcode. Pickers scan items using handheld devices, and the system validates them against the order in real time.

If the wrong product, variation, or quantity is picked, the system blocks the process and prompts for correction. This validation at the source significantly reduces

- SKU mismatches

- Size or color variation errors

- Incomplete combos or bundles

For sellers with large catalogs or similar looking SKUs, barcode scanning alone can cut pick errors by over 90 percent.

3. Smart Slotting and Digital Location Mapping

Automation platforms optimize where each SKU is stored based on factors like sales velocity, order patterns, and packaging type. Fast moving items are placed closer to pack stations. Lookalike SKUs are separated across zones to reduce visual confusion.

These platforms also generate digital pick paths to minimize walking time and picker fatigue. As a result

- Orders are picked faster and more accurately

- New staff can learn locations quickly

- Warehouse layout evolves with order volume and trends

This is particularly valuable during seasonal spikes or when scaling across multiple cities.

4. Automated Packing Verification

Packing is a common failure point. Items may be missed, incorrectly packed, or poorly secured. Automated systems resolve this by enforcing digital checks at every step

- Pack station shows a visual of each item in the order

- Every item must be scanned again before it goes into the box

- The system recommends optimal box size and packing material

- Shipping label and invoice are auto generated and matched

Nothing can be sealed or shipped until all checks pass. This removes the guesswork from packing and ensures every order is complete, secure, and correctly labeled.

5. Real Time Inventory Updates

Inventory is updated in real time as soon as items are picked, packed, or returned. There is no delay, no spreadsheet reconciliation, and no manual adjustment required. This allows

- Instant stock sync across marketplaces and DTC platforms

- Prevention of overselling or shipping out of stock items

- Trigger based reordering and low stock alerts

It also eliminates order cancellations due to unavailable inventory, which improves seller scores and customer satisfaction.

6. Error Tracking and Root Cause Analysis

Automation platforms log every action who picked what, when, and from where. If there is an error, managers can trace it back to the individual step where it occurred whether during pick, pack, or handover.

This allows

- Rapid identification of high error SKUs or warehouse zones

- Targeted training for underperforming staff

- Process redesign based on real data

Instead of reactive firefighting, sellers can now manage fulfillment proactively with structured workflows and continuous improvement.

7. Scalability Without Growing Headcount

As order volumes rise, manual systems need more labor, more supervision, and more space. Automated fulfillment scales differently. The same system that handles 100 orders a day can manage 1000 with minimal changes because accuracy and speed are system driven, not person dependent.

This allows small teams to

- Run high volume operations with fewer errors

- Manage fulfillment across multiple warehouses

- Maintain consistency even with new or temporary staff

Final Thoughts

In Indian eCommerce, competition is rising, margins are shrinking, and customer expectations are higher than ever. Every mispick, wrong shipment, or return due to poor packing is not just an operational error. It is lost trust, wasted money, and a missed opportunity to grow.

The truth is simple. Manual processes may work when you are small, but they will break as you scale. Automation is not just about speed or convenience. It is about building a system that can deliver consistently, accurately, and profitably even as your order volume grows.

Whether you are selling on a marketplace, running your own DTC brand, or doing both, fulfillment is your last and most important touchpoint with the customer. Get it right and you win loyalty. Get it wrong and they may never come back.

If your business is ready to grow, your operations must be ready to support that growth. Automation is how you get there. Connect with Base.com today!

Click here to know more about Amazon FBA vs FBM vs Seller Flex: which model maximizes profits for Indian sellers?

Frequently Asked Questions

Q1: What are picking errors?

Picking errors occur when the wrong product, quantity, or variant is selected during order fulfillment. This can include sending the wrong size, color, or even missing items entirely. Such errors lead to returns, increased costs, customer dissatisfaction, and a negative impact on seller ratings and profit margins.

Q2: What is picking and packing?

Picking involves locating and retrieving the correct items from warehouse shelves after an order is received. Packing is the next step, where items are securely packaged, labeled, and prepared for shipment. Together, these two steps are essential in ensuring accurate and timely delivery in eCommerce fulfillment.

Q3: How to reduce picking errors in a warehouse?

To reduce picking errors, implement barcode scanning, organized SKU slotting, and a warehouse management system. Train staff regularly and use real time verification tools. Ensuring clear labeling and optimized pick paths also helps minimize confusion, reduce walking time, and improve picking speed and accuracy.

Q4: How do you ensure accuracy when picking and packing orders?

Use barcode validation, digital checklists, and packing SOPs to verify every item before shipment. Implement a final scan step at the pack station. Automated systems that match products to orders in real time are critical in maintaining high accuracy and reducing manual errors during fulfillment.