Global supply chain issues have consistently caused stockouts, a significant problem that costs retailers nearly $1 trillion globally every year, with almost 70% of online shoppers abandoning their purchase and often moving to a competitor when an item is unavailable.

In Indian e-commerce, the difference between a thriving enterprise and one struggling to survive often boils down to a single, critical metric: inventory management. For sellers operating across major marketplaces like Amazon India, Flipkart, and Meesho, along with their own Direct-to-Consumer (D2C) channels, the dual challenges of preventing costly stockouts and achieving a high Order Fill Rate are constant battles. A stockout leads to a lost sale and an unhappy customer. A low fill rate causes operational problems and harms the brand’s reputation.

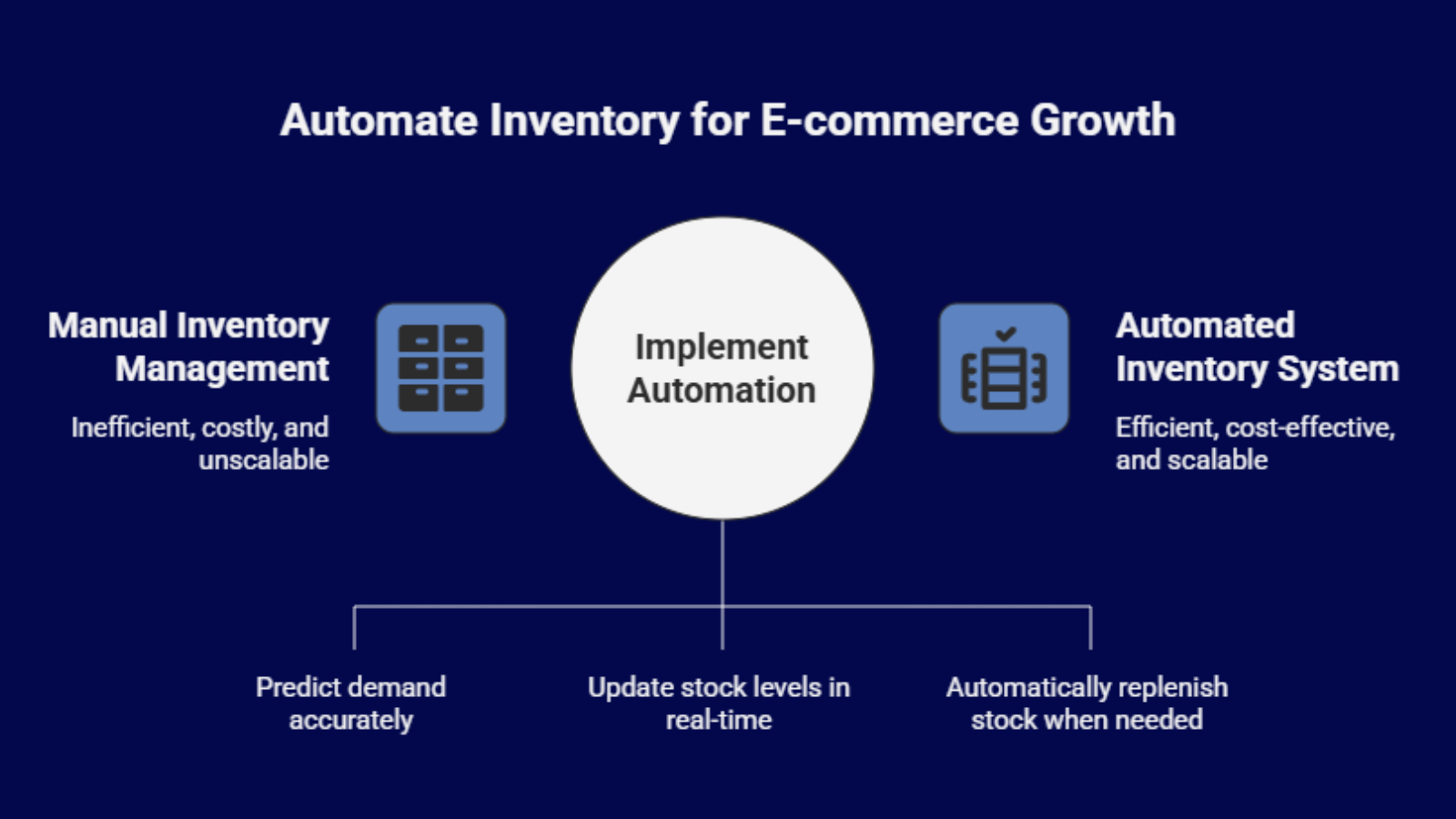

The solution, increasingly, lies in the strategic deployment of e-commerce automation. This technology-driven approach moves beyond manual spreadsheets and guesswork, offering Indian sellers a powerful toolkit to optimize their supply chain, predict demand with greater accuracy, and ensure the right product is in the right place at the right time.

This comprehensive guide delves into how automation fundamentally transforms inventory management, providing a clear roadmap for Indian e-commerce businesses to drastically reduce stockouts, significantly boost their Fill Rate, and unlock a new dimension of scalability and customer loyalty.

How do stockouts and low fill rates directly translate into lost sales and missed revenue for e-commerce sellers in India?

For the Indian e-commerce seller, the operational stakes are exceptionally high, driven by festival sale peaks (Diwali, Holi), complex multi-channel operations, and a demanding customer base accustomed to rapid delivery.

A. The Hidden Costs of Stockouts

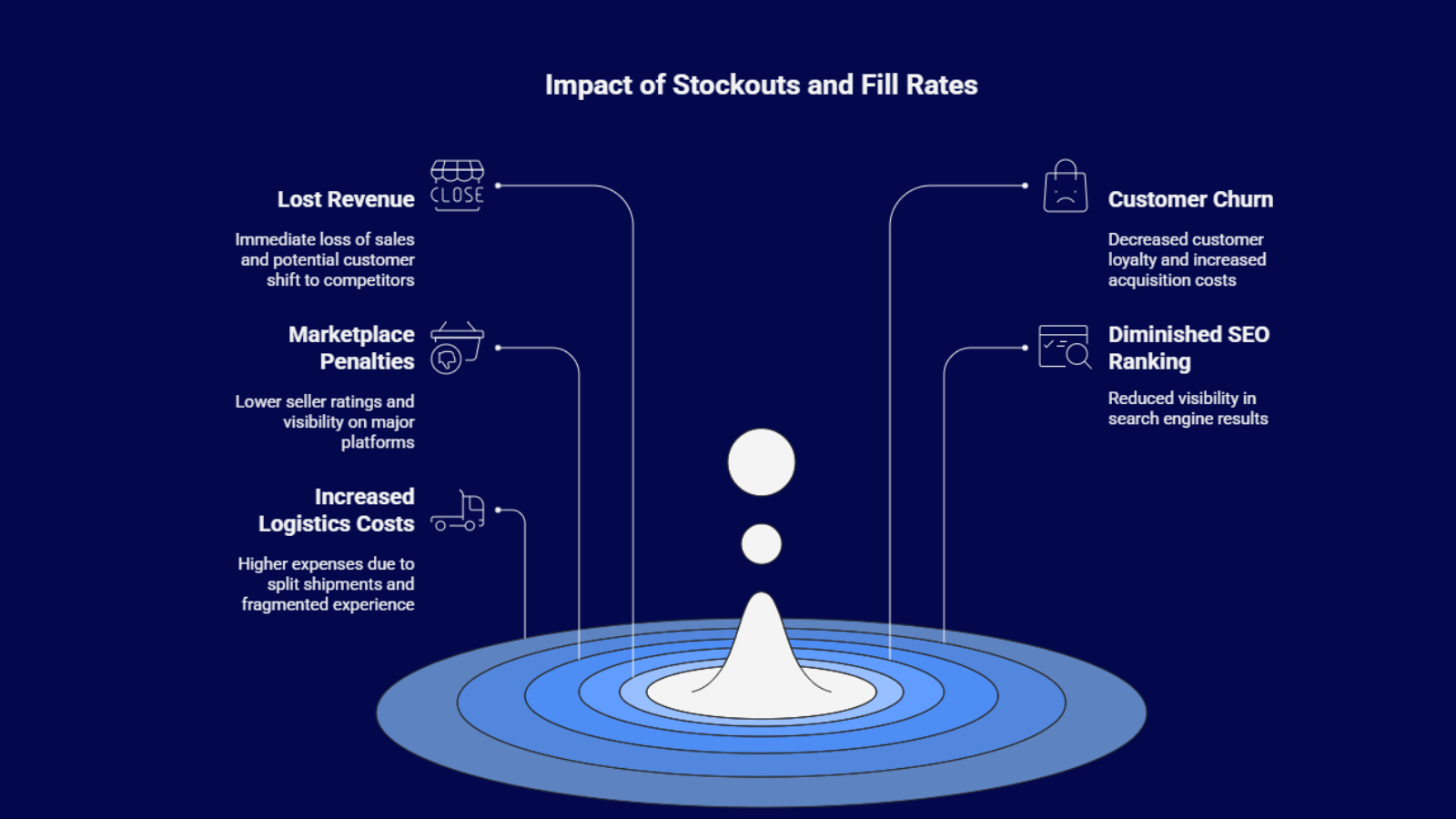

A stockout is more than just a missed transaction; it incurs cascading costs that erode long-term profitability:

- Lost Revenue: The immediate loss of a sale, often compounded by the customer moving to a competitor.

- Customer Churn: Repeated stockouts lead to customer frustration, decreased loyalty, and a higher Customer Acquisition Cost (CAC) for future sales.

- Marketplace Penalties: Major marketplaces often penalize sellers for order cancellations due to out-of-stock items, impacting seller ratings, visibility, and Buy Box eligibility.

- Diminished SEO/GEO Ranking: Consistent unavailability can signal poor service to search engines and marketplaces, leading to lower organic and platform-specific rankings.

B. The Imperative of a High Fill Rate

The Fill Rate, the percentage of customer orders fulfilled completely from available stock is a true measure of inventory health and customer satisfaction.

| Fill Rate Metric | Definition | Impact on Indian Seller |

|---|---|---|

| Order Fill Rate | Orders completely fulfilled (all items available) / Total Orders | Direct link to customer satisfaction and review score. |

| Line Item Fill Rate | Total line items shipped / Total line items ordered | Measures service level precision; critical for kits/bundles. |

| Value Fill Rate | Value of goods shipped / Value of goods ordered | Focuses on minimizing loss on high-value/high-demand items. |

A low fill rate means more split shipments, higher logistics costs, and a fragmented customer experience, directly hindering scalability, especially during peak sales.

How to decrease Stockouts and Boost Fill Rate?

Automation leverages advanced software to perform repetitive, data-heavy, and error-prone tasks faster and with greater accuracy than human effort, thereby closing the gaps that lead to stockouts.

1. Automated, AI-Driven Demand Forecasting

Manual forecasting using simple historical data is insufficient for the dynamic Indian market, which is heavily influenced by regional festivals, weather patterns, and competitive flash sales.

- Real-Time Data Aggregation: Automation tools integrate with all sales channels (Amazon, Flipkart, D2C website) and centralize data.

- Predictive Analytics: AI-powered algorithms analyze multi-dimensional data points:

- Historical Sales: Identifying day-of-week, time-of-year, and last-mile delivery trends.

- External Factors: Integrating local calendar events (regional holidays), promotional schedules, and even competitor pricing changes.

- Proactive Stock Allocation: The system automatically forecasts optimal stock levels for each Fulfillment Center (FC) or dark store based on geographical demand prediction, preventing stockouts in high-demand zones while avoiding overstocking elsewhere.

2. Dynamic, Real-Time Inventory Synchronisation

Overselling an item that is already out of stock on another channel is a primary cause of stockouts and cancellations.

- Multi-Channel Master Data: A central Inventory Management System (IMS) acts as the single source of truth for stock levels.

- Instant Syncing: Automation ensures that the moment a product is sold on one channel (e.g., When a customer places an order on Flipkart, the system instantly updates the inventory count and syncs it across all other connected channels (Amazon, Shopify, etc.)

- Safety Stock Triggers: The system automatically reserves a defined quantity of safety stock and issues alerts or locks selling on a channel when the stock dips below a critical, pre-defined Reorder Point.

3. Smart, Automated Reorder Point Optimisation (RPO)

Relying on a fixed reorder point leads to missed opportunities or stockouts when lead times or demand change.

- Automated RPO Calculation: The system dynamically calculates the optimal reorder quantity and timing by factoring in:

- Sales Velocity: How fast the product is selling currently.

- Supplier Lead Time: The variable time it takes for a supplier in a specific region of India to deliver stock.

- Service Level Target: The desired percentage of orders to be fulfilled (e.g., aiming for a 99% Fill Rate).

- Automated Purchase Order (PO) Generation: When the stock hits the dynamic Reorder Point, the system auto-generates a Purchase Order with the optimal quantity, sends it to the pre-approved vendor, and tracks the delivery status, eliminating manual follow-up and human error.

4. Optimized Order Routing and Fulfillment

Automation ensures orders are fulfilled from the best possible location, minimizing shipping time and avoiding local stockouts.

- Smart Location Assignment: Orders are automatically routed to the warehouse or fulfillment centre closest to the customer that has the product in stock. This prioritizes the fastest delivery while preserving central stock for other regions.

- Split-Order Logic: For multi-item orders where stock is decentralized, automation can determine the most cost-effective and fastest way to fulfill the order, either by consolidating items or intelligently splitting the shipment, ensuring the customer receives as many items as possible (boosting Line Item Fill Rate).

What are the Tangible Benefits of Automation for Indian E-commerce Sellers?

Moving to an automated inventory system is a strategic investment that yields quantifiable returns across the entire operation.

A. Quantifiable Improvement in Fill Rate

By combining precise forecasting, instant synchronisation, and smart reorder systems, automation directly addresses the root causes of unfulfilled orders. Sellers commonly report an improvement in Order Fill Rate within the first six months of implementation.

B. Significant Reduction in Operational Costs

- Reduced Expedited Shipping: Smart order routing ensures orders are shipped from the nearest, most appropriate location, cutting down on expensive last-minute or cross-country expedited logistics.

- Lower Holding Costs: Accurate demand forecasting prevents costly overstocking, freeing up working capital and reducing warehouse rental expenses.

- Reduced Manual Labor: Automating PO generation, stock alerts, and channel updates frees up skilled manpower to focus on high-value tasks like customer service and strategic sourcing.

C. Scalability and Multi-Channel Resilience

Automation is the engine for growth. As an Indian seller expands from one marketplace to a D2C website and a third marketplace, a manual system breaks down. Automation ensures inventory accuracy, order processing speed, and fulfillment logic scale seamlessly, allowing the business to handle huge order volumes during festive seasons without a corresponding increase in operational staff.

Ready to Automate Your Inventory and Scale Your E-commerce Business?

Conclusion

For the modern Indian e-commerce seller, the era of manual inventory management is over. Stockouts and low fill rates are no longer just operational hurdles; they are existential threats in a market defined by speed and reliability. Implementing a robust automation strategy, one that covers forecasting, real-time syncing, and smart reordering, is the most effective way to secure a competitive edge. It is the definitive path to achieving greater profitability, higher customer satisfaction, and the operational resilience needed to scale successfully across all of India’s booming sales channels.

Take the first step toward flawless fulfillment today. Visit base.com to see how our inventory solutions are empowering top Indian sellers.

Frequently Asked Questions (FAQs) for Indian Sellers

Q1: Is e-commerce automation too expensive for Small and Medium Businesses (SMBs) in India?

A: No. The cost of manual error, including stockout-related penalties and lost sales, typically far outweighs the subscription cost of modern inventory automation software. Many cloud-based solutions are available on a scalable, pay-as-you-go model, making them highly accessible and providing a clear Return on Investment (ROI) even for smaller sellers managing multiple marketplaces.

Q2: How does automation handle festival season peak demand, like Diwali or Republic Day Sales?

A: Automation is critical for peak season. The system analyzes historical festive sales data, identifies specific product spikes (e.g., traditional wear vs. electronics), and automatically increases the safety stock levels and reorder points only for the necessary periods. This ensures you have optimal stock to meet the surge without massive overstocking once the sale ends.

Q3: We sell on both Amazon and our D2C website. Can automation sync inventory between two such different platforms?

A: Yes, this is one of the core benefits. Automation systems, often implemented through an Inventory Management System or Order Management System, use APIs to integrate directly with all major Indian marketplaces and D2C platforms (Shopify, WooCommerce, etc.). This integration delivers true, real-time, two-way synchronization, instantly updating stock across all channels, eliminating overselling, and maximizing your potential for a 100% accurate fill rate.