Every e-commerce business relies on one simple truth: you cannot sell what you do not have, and you cannot profit from what you cannot move. Inventory management, the discipline of ensuring the right product is available at the right time and in the right place is the core engine of your online store. Yet, this critical function is often plagued by mistakes that silently erode profit margins, frustrate customers, and stunt growth.

For e-commerce, the stakes are exceptionally high. Customers expect real-time stock transparency and rapid fulfillment. A single inventory error can lead to a dreaded stockout, a negative review, or the long-term loss of a loyal buyer.

This deep-dive guide breaks down the five most common and costly inventory management mistakes that e-commerce businesses make. More importantly, it provides a complete, actionable blueprint for optimizing your stock control using modern techniques and software, with specific considerations for Indian sellers navigating complex logistics and compliance requirements.

The Five Most Critical E-commerce Inventory Management Mistakes (with an Indian Market Lens)

The following inventory management mistakes are consistently identified as the biggest challenges for growing online retailers. They represent a fundamental lack of visibility and control, often leading to a financial triple threat: lost sales, excess holding costs, and operational inefficiencies.

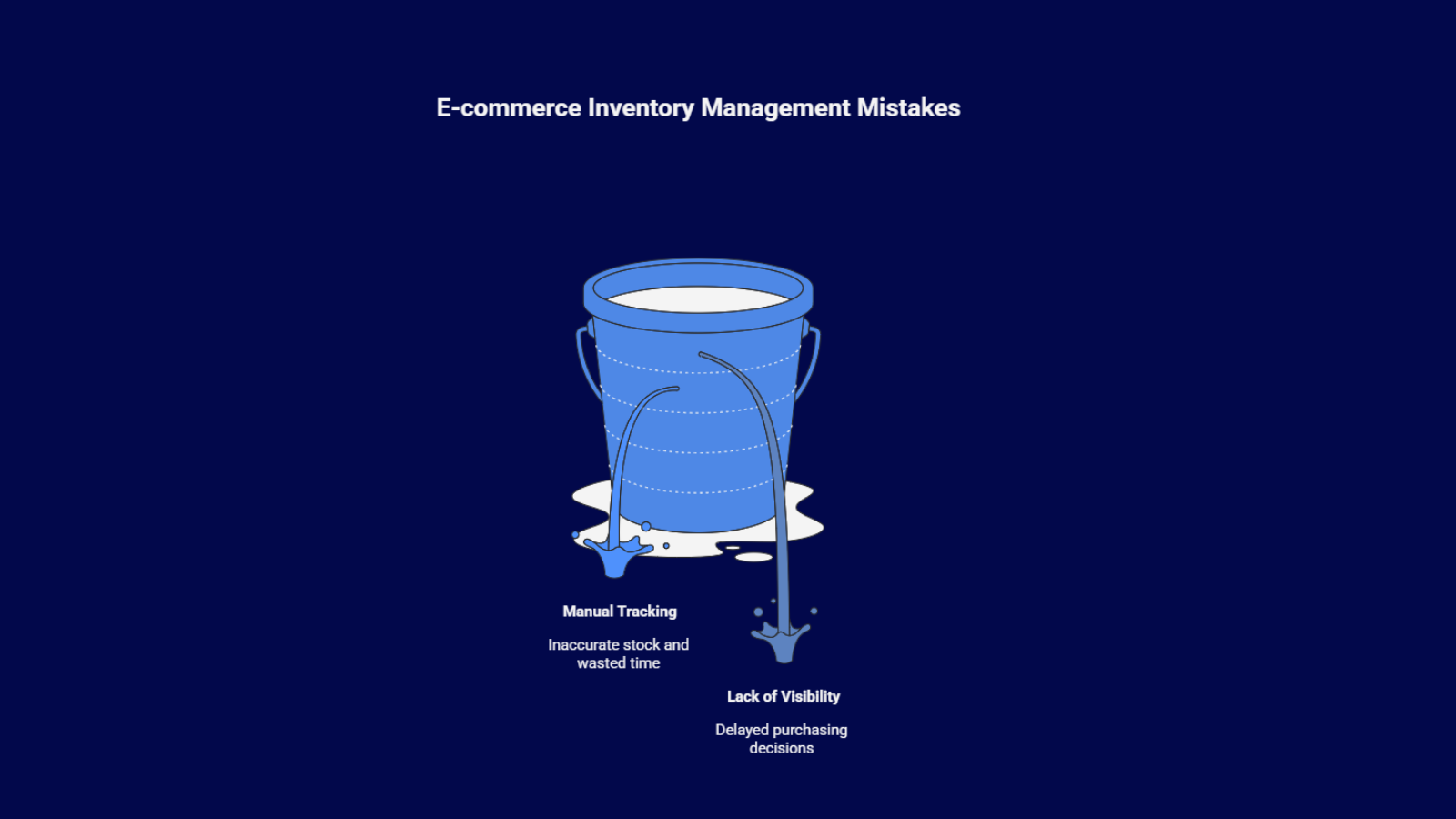

Mistake 1: Relying on Manual Tracking (The Spreadsheet Trap)

The single biggest bottleneck for scaling e-commerce businesses is the reliance on manual tracking systems like spreadsheets. As soon as a business exceeds 50 SKUs or begins selling on multiple channels (e.g., website, Amazon, Flipkart, Meesho), Excel fundamentally becomes a liability.

The Costly Consequence

- Inaccurate Real-Time Stock: Manual data entry virtually guarantees human error. A single typo or missed update means your website displays a product as “In Stock” when it is already sold out, resulting in overselling, customer cancellations, and brand damage across multiple platforms.

- Wasted Time: Employees spend unproductive hours reconciling spreadsheets, searching for misplaced stock, and manually generating reorder lists, time that should be dedicated to customer service or marketing.

- Delayed Decisions: Prudent, timely purchasing decisions are impossible if your inventory data is days or weeks out of date.

How to Avoid It: Implement Real-Time, Centralized Control

The solution is mandatory for scalability: Centralize your inventory data using a dedicated Inventory Management System (IMS) or Enterprise Resource Planning (ERP) platform.

| Action Point | Key Strategy | Optimization Goal |

| Unified Data Model | Integrate your IMS with all sales channels (e.g., Shopify, Amazon, Flipkart, POS) to ensure every sale instantly deducts stock from one central pool. | Eliminate overselling and stock discrepancies across marketplaces. |

| Barcode/Scanning Technology | Implement barcode scanners and mobile applications in the warehouse to record stock-in, transfers, and picking/packing processes in real time. | Drastically reduce human data entry errors and increase pick-pack efficiency. |

| Automated Updates | Ensure all returns, damages, and cycle counts are logged directly into the system, establishing a “single source of truth” for stock levels. | Provide accurate inventory visibility to customers and staff. |

Mistake 2: Inaccurate or Non-Existent Demand Forecasting

Ordering based on intuition or simply replicating the previous year’s order is a formula for failure. E-commerce demand is volatile, driven by social media, promotions, and global events. Poor demand forecasting is the primary cause of both overstocking and understocking. For Indian sellers, forecasting must account for major regional and national festivals (e.g., Diwali, Holi, Eid) which cause massive, predictable spikes.

The Costly Consequence

- Understocking (Stockouts): Leads to lost revenue, immediate loss of customer trust, and long-term customer churn, especially during high-demand events like the Big Billion Days/Great Indian Festival.

- Overstocking (Dead Stock): Ties up valuable capital in unsold goods, leading to increased holding/carrying costs, warehouse space depletion, and eventual markdowns. This significantly impacts cash flow.

- Missed Trends: Failing to predict a seasonal spike or emerging product trend results in rushed, costly restocking and slower lead times.

How to Avoid It: Leverage Data-Driven Forecasting

Inventory optimization depends on your ability to predict future demand or, at minimum, use historical data to inform it.

- Analyze Historical Data: Go beyond aggregate sales. Segment data by SKU, sales channel, geography, and time of day/week/year. Look for patterns correlating with promotions, holidays, and marketing expenditures.

- Calculate Safety Stock: Determine the minimum stock buffer required to cover maximum demand fluctuations during the supplier lead time.

Safety Stock = (Maximum Daily Usage × Maximum Lead Time) – (Average Daily Usage × Average Lead Time)

- Factor in Festival/Seasonal Peaks: Integrate specific historical demand data for major Indian festivals and sale events into your reorder planning. This is crucial for avoiding stockouts during your highest revenue-generating windows.

- Factor in Lead Time: Constantly track the time from placing a Purchase Order (PO) to receiving stock. Longer lead times necessitate higher safety stock and earlier reorder points.

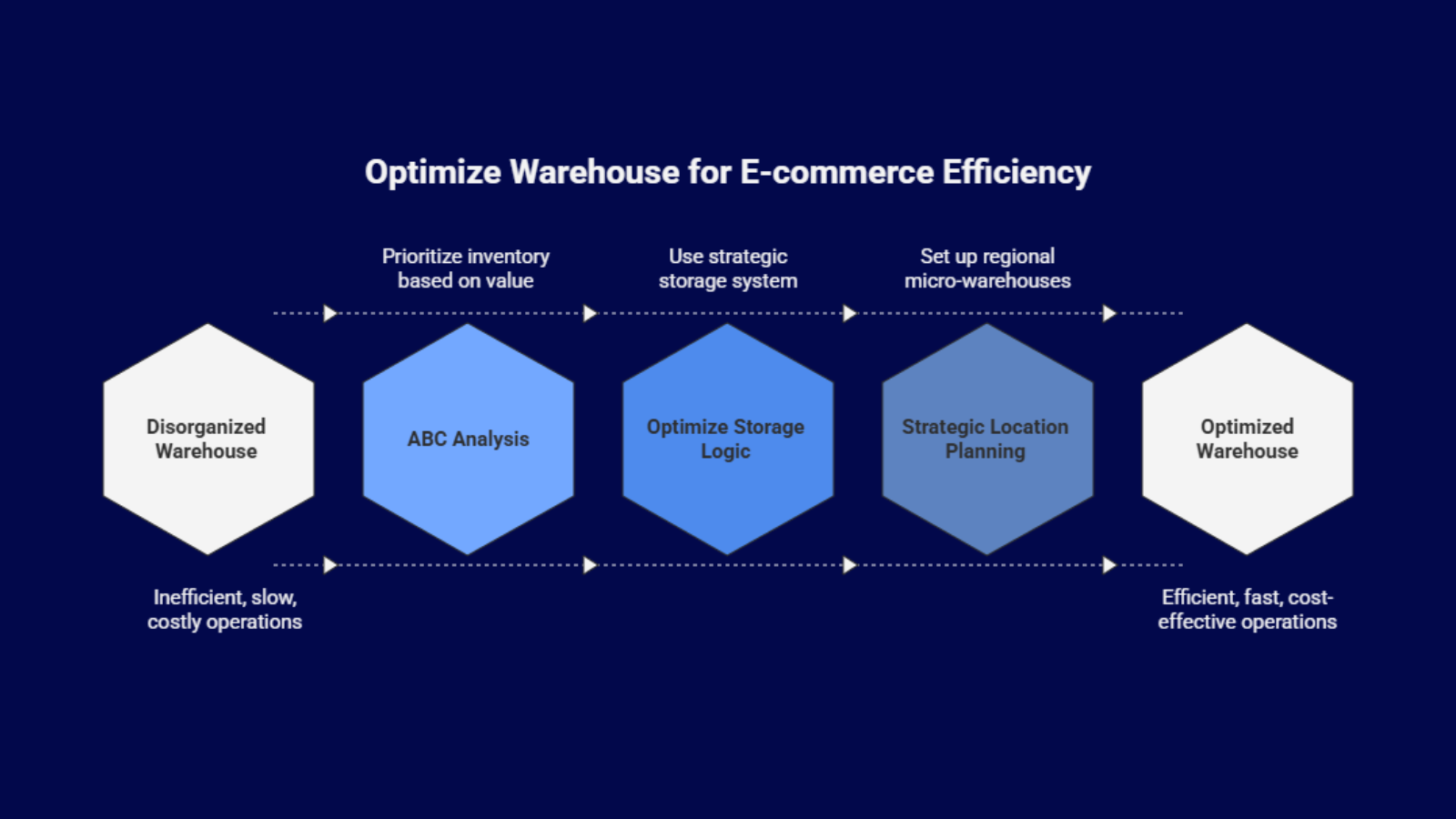

Mistake 3: Poor Warehouse Location Strategy and Organization

Many e-commerce operations expand haphazardly from a smaller space into a commercial warehouse. A disorganized warehouse is not merely messy; it is a source of massive inefficiency, slow fulfillment, and high labor costs. In India, the complexity of inter-state logistics necessitates a strategic, decentralized approach.

The Costly Consequence

- Slow Picking Time: Staff waste time walking long distances or searching for misplaced items, directly increasing the cost per order fulfillment and delaying customer delivery.

- Increased Errors: A disorganized, non-standardized environment contributes to more picking errors (shipping the wrong product), which results in high return rates, costly reshipments, and dissatisfied customers.

- High Logistics Costs: Without strategically placed fulfillment centers (even small ones), you rely on longer transit routes, incurring higher freight costs and extending delivery times.

How to Avoid It: Implement ABC Analysis and Optimize Layout/Location

Organization is centered on operational flow, not just neatness. Your layout must prioritize the movement of your fastest-selling goods.

- Perform ABC Analysis: Categorize your inventory based on value and sales frequency:

- A Items (Top 20%): High-value, high-frequency sellers (must be stored closest to the packing/shipping station).

- B Items (Middle 30%): Moderate sellers (stored in an easily accessible zone).

- C Items (Bottom 50%): Low-value, slow-moving items (can be stored in less accessible areas).

- Optimize Storage Logic: Use a strategic system (e.g., Fixed Location for high-value items, Random Location for bulk items). Ensure all locations are clearly labeled with unique bin/shelf codes.

- Strategic Location Planning: Leveraging GST simplification, consider setting up regional micro-warehouses/mini-fulfillment centers near high-demand pin codes or metro hubs to reduce last-mile delivery time and costs. This is key to competing with marketplace fulfillment speeds.

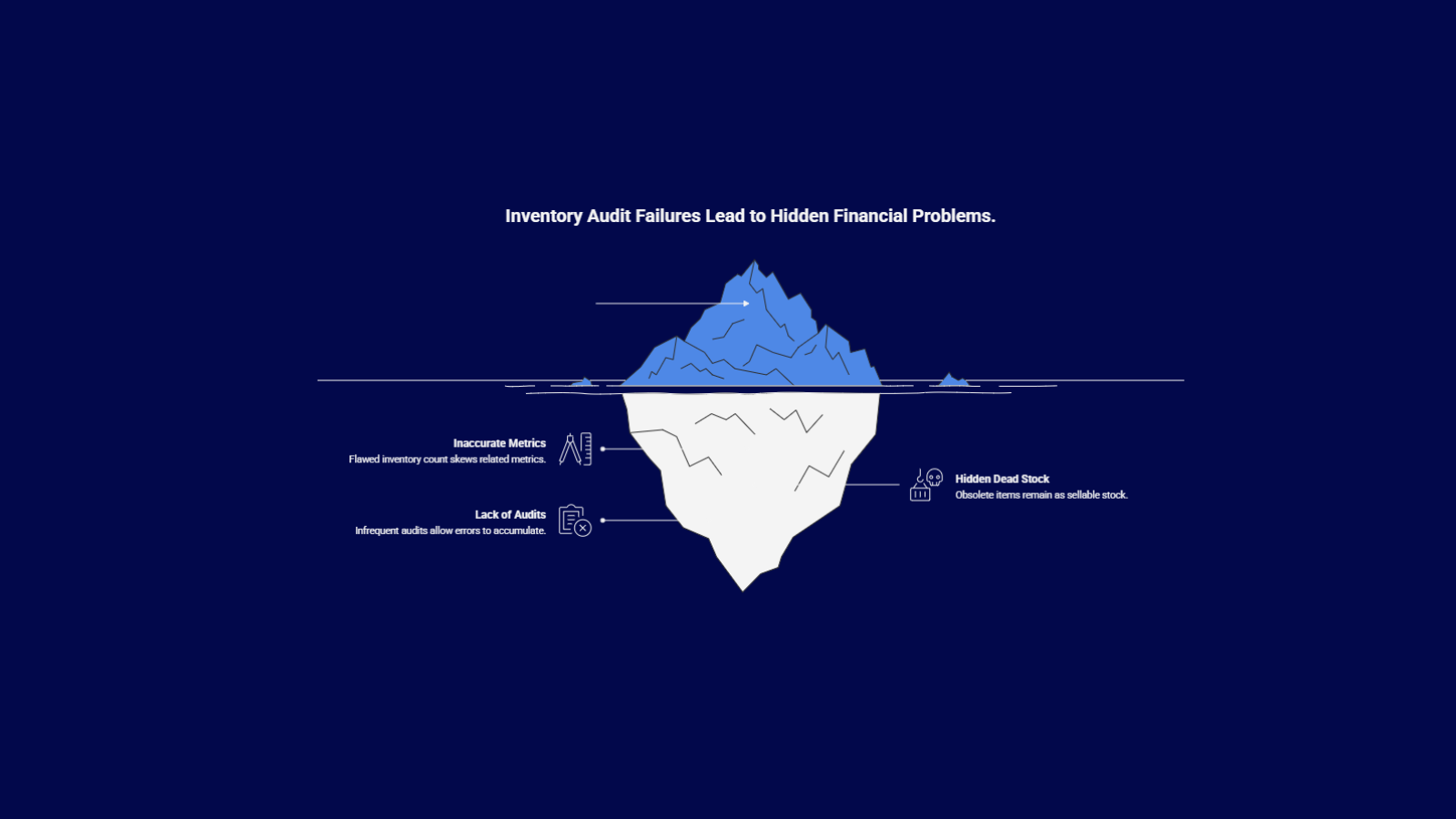

Mistake 4: Failing to Conduct Regular Inventory Audits (Cycle Counting)

A discrepancy between your physical stock count and your system’s recorded count is known as shrinkage, encompassing theft, damage, and administrative errors. Failing to audit inventory regularly allows these errors to accumulate until they create a significant financial problem.

The Costly Consequence

- Massive Annual Write-Offs: Businesses frequently discover thousands of rupees in missing or damaged stock only during the disruptive annual physical count.

- Inaccurate Metrics: If your baseline inventory count is incorrect, every related metric – inventory turnover rate, stock value, and cash flow projections is also flawed.

- Hidden Dead Stock: Items that should have been marked as damaged, expired, or obsolete remain in the system as sellable stock, skewing all operational data.

How to Avoid It: Shift from Annual to Perpetual Inventory

Eliminate the disruptive annual warehouse shutdown for stocktaking. Adopt Perpetual Inventory via Cycle Counting.

- Cycle Counting: Instead of closing the entire warehouse, count a small, specific section of inventory every day, week, or month.

- Prioritization: Count A-items more frequently (daily/weekly) due to their high value and fast turnover.

- Systematic Counts: Count C-items less frequently (quarterly/annually).

- Dedicated Team: Assign a small, thoroughly trained team to perform cycle counts using a tablet or handheld scanner. This maintains data accuracy and assigns accountability to specific personnel.

- Reconciliation: Instantly reconcile any count discrepancy in the system. The discrepancy itself should be recorded as a Key Performance Indicator (KPI) to track and address the root cause (e.g., deficiencies in the receiving process or picking errors).

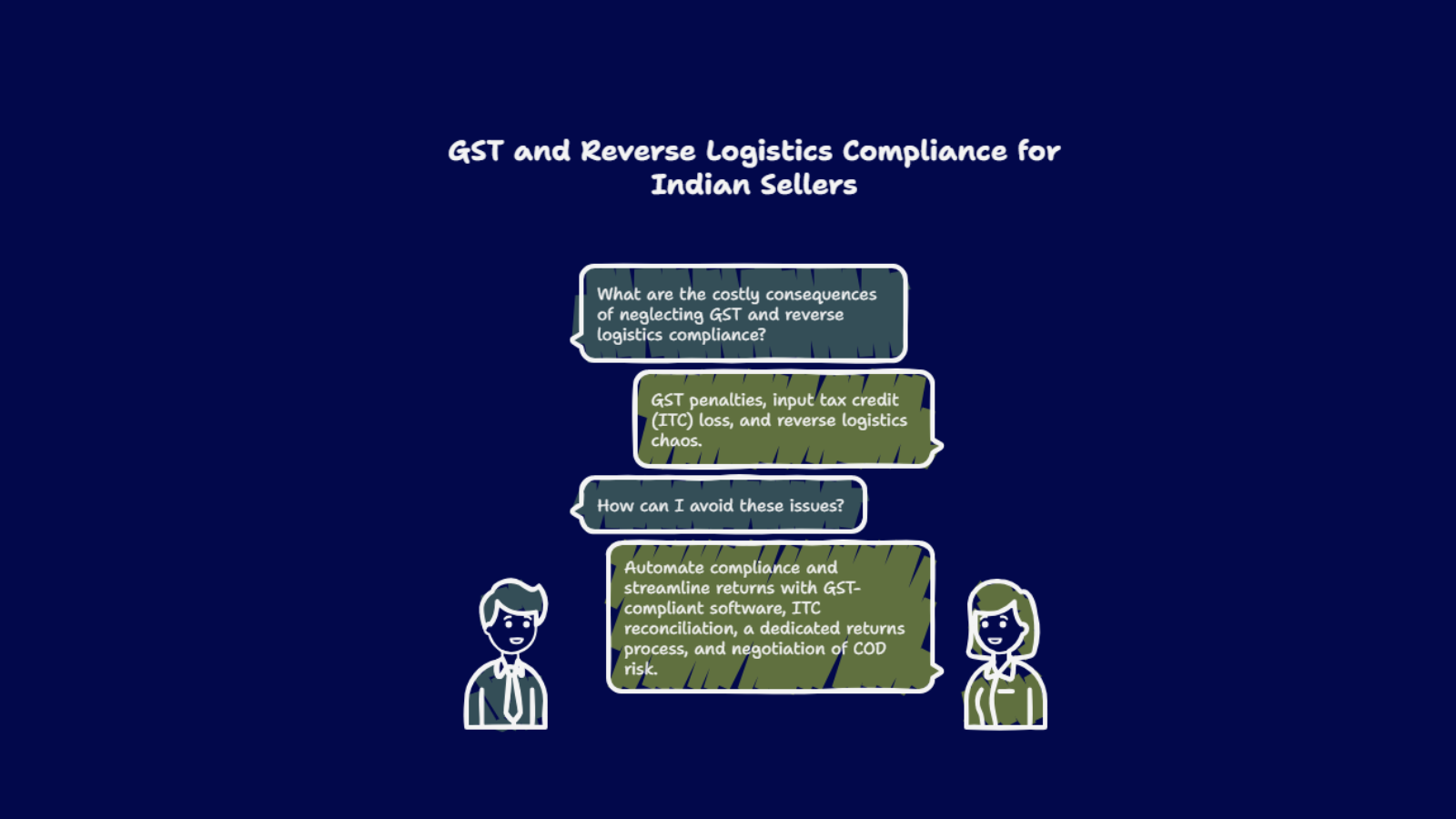

Mistake 5: Neglecting GST and Reverse Logistics Compliance

For Indian sellers, inventory is inextricably linked to tax compliance and managing high return rates. Ignoring the compliance aspect or treating returns as a secondary issue can result in major financial penalties and loss of customer trust.

The Costly Consequence

- GST Penalties: Incorrect classification of goods, failure to generate GST-compliant invoices (including HSN codes), or delayed filing of returns based on inaccurate stock data can lead to significant penalties.

- Input Tax Credit (ITC) Loss: Manual or faulty record-keeping means you may miss out on claiming eligible ITC on purchases, directly increasing your cost of goods sold and eroding profit margins.

- Reverse Logistics Chaos: E-commerce in India often sees high return rates, especially for apparel and electronics. Treating returned stock as waste, or delaying its inspection and restock, leads to unsellable inventory cluttering the warehouse and delaying customer refunds.

How to Avoid It: Automate Compliance and Streamline Returns

Treat your supplier relationships as a strategic asset.

- GST-Compliant Software: Mandate the use of inventory software that automatically generates GST-compliant invoices (with accurate HSN codes), manages the ledger, and assists in preparing data for GSTR-1 and GSTR-3B filings. This is non-negotiable for scale.

- ITC Reconciliation: Use your system to regularly reconcile purchase invoices against your stock received to maximize your Input Tax Credit claims.

- Dedicated Returns Process (Reverse Logistics): Implement a robust, dedicated process for returns (reverse logistics). All returned products must be immediately inspected, classified (e.g., Resellable, Damaged, Repair), and the sellable stock instantly added back to the inventory pool. Speed in processing returns is critical for customer satisfaction.

- Negotiate COD Risk: Given the high prevalence of Cash-on-Delivery (COD) in the Indian market, track COD RTO (Return to Origin) rates by pin code and product category to identify high-risk areas, informing your inventory allocation strategy.

E-commerce Inventory Optimization: The Way Forward for Indian Businesses

Avoiding the five inventory management mistakes detailed above is a strong beginning, but true e-commerce growth necessitates optimization. The future of stock control is data-driven automation.

The Pillars of Modern Inventory Optimization

| Pillar | Core Strategy | Key Benefit |

| ABC/Pareto Analysis | Focus management time on the A-items (20% of stock that generates 80% of revenue) to ensure maximum profitability and near-zero stockouts. | Maximized Return on Investment (ROI) on management time. |

| Inventory Turnover Rate (ITR) | Continuously monitor your ITR to identify slow-moving products (low ITR) that require promotion or clearance. | Increased cash flow and reduced holding costs. |

| Just-in-Time (JIT) Principles | For predictable, stable products, adopt JIT by ordering stock only as needed, minimizing warehousing costs and dead stock risk. This works best when Indian supplier reliability is high. | Lower capital commitment and reduced warehousing overhead. |

| Multichannel Synchronization | Utilize an IMS that provides a single, unified pool of inventory across all your marketplaces (Amazon, Flipkart) and storefronts to prevent overselling on any channel. | Consistent customer experience and reliable order fulfillment. |

Click here, to learn more about the future of e-commerce operations and how will oms & wms shape it.

Take Control and Scale Your E-commerce Business

Inventory management is not a routine task; it is a strategic competitive advantage. By transitioning away from manual spreadsheets, embracing data-driven forecasting, and optimizing your physical processes while ensuring GST compliance, you transform your stock from a costly liability into a dynamic, profitable asset.

Do not allow these five common mistakes to impede your growth. Implement these strategies today to elevate your e-commerce operations.

Ready to automate your inventory, eliminate stockouts, and regain control of your cash flow?

Start your free trial of a robust, e-commerce-focused inventory solution at Base.com today.

Frequently Asked Questions

1. What is a “good” Inventory Turnover Rate (ITR)?

A healthy ITR is typically between 4 and 10 times per year, though it varies by industry. A low ITR means capital is tied up in unsold stock, while an excessively high ITR might indicate a stockout risk.

2. How should I calculate and determine the Reorder Point?

The Reorder Point (ROP) ensures you restock before running out. An Inventory Management System should automate this calculation and send alerts to prevent manual errors and avoid costly stockouts.

3. What is the most common inventory valuation method used in India?

The most common methods for e-commerce inventory valuation in India are FIFO (First-In, First-Out) and the Weighted Average Cost (WAC) method. FIFO is preferred for perishable or trend-based goods, as it accurately matches physical flow. LIFO is generally not permitted under Indian Accounting Standards.

4. What are the best strategies for clearing Dead Stock?

To clear dead stock, use strategies to recover capital and free up space. Key tactics include product bundling with best-sellers, running deep clearance sales, offering the stock as a free gift with a high-value purchase, or utilizing tax benefits by donating the obsolete items.