Running a warehouse with a small team can be tough and high stakes. Research shows that warehouses contribute to nearly one in four workplace injuries in the logistics industry, often caused by slips, mishandling of equipment, and cluttered spaces. For small sellers, where every worker juggles multiple responsibilities, the risks are amplified.

A well designed warehouse safety checklist acts as a game changer, helping cut accidents by up to 40 percent, boosting compliance, and protecting valuable inventory. With clear safety protocols, small teams can achieve seamless operations, secure employees, and long term business success.

In this blog, we will walk through a practical warehouse safety checklist designed specifically for small sellers. You will learn how structured safety practices can minimize accidents, protect inventory, and ensure compliance with regulations.

By the end, you will see how adopting these steps not only safeguards your employees but also helps you build efficiency, maintain customer trust, and scale your business with confidence.

Why Safety Matters for Small Teams?

For small sellers managing their own warehouses or storage facilities, safety is more than a compliance requirement. It directly affects efficiency, customer experience, and long term profitability. Unlike large enterprises that can absorb disruptions, small teams operate with limited resources where every worker, every square foot of storage, and every unit of inventory matters. A warehouse safety checklist provides structure that helps sellers maintain consistency, reduce risks, and protect both people and property.

Building a Safety Culture

In a small warehouse, employees often perform multiple tasks in the same shift. One worker may unload shipments in the morning, pick orders in the afternoon, and handle packaging in the evening. In such settings, accidents are more likely if safety is not ingrained in everyday behavior. Creating a culture where safety rules are followed without exception ensures smoother operations. Sellers can achieve this through regular training sessions, visual reminders across the facility, and by rewarding safe behavior. When employees feel that safety is valued, they are more engaged and committed to meeting service level agreements.

Reducing Operational Risks

Every accident has a financial impact. A fall on a slippery floor can delay shipments. A collapsed storage rack can destroy inventory worth lakhs of rupees. Even minor disruptions can cause missed marketplace deadlines and order cancellations, which lower seller ratings. By using a checklist to remove hazards, maintain equipment, and verify compliance, sellers reduce the risk of revenue leakage. For example, ensuring that forklifts are inspected daily prevents sudden breakdowns during peak hours, which could otherwise delay dispatches.

Meeting Compliance Standards

E-commerce marketplaces and logistics partners increasingly require sellers to follow safety and audit guidelines. Programs such as Fulfilled by Amazon or Flipkart Smart Fulfillment assess warehouse conditions before onboarding. Non compliance can lead to failed audits, exclusion from premium services, or even penalties. A well implemented safety checklist ensures readiness for inspections and demonstrates professionalism to both regulators and business partners. Sellers that meet these standards gain access to faster shipping options and higher customer trust.

Protecting People and Assets

Small sellers cannot afford frequent downtime or costly compensation claims. Employees are valuable assets and their safety determines business continuity. At the same time, inventory and equipment must be safeguarded against damage. A structured safety program reduces risks to both. For instance, properly labeling hazardous materials prevents accidental misuse, while maintaining ventilation protects goods stored in sensitive conditions. Ultimately, protecting people and assets is protecting the business itself.

What are the Key Safety Steps for Small Teams?

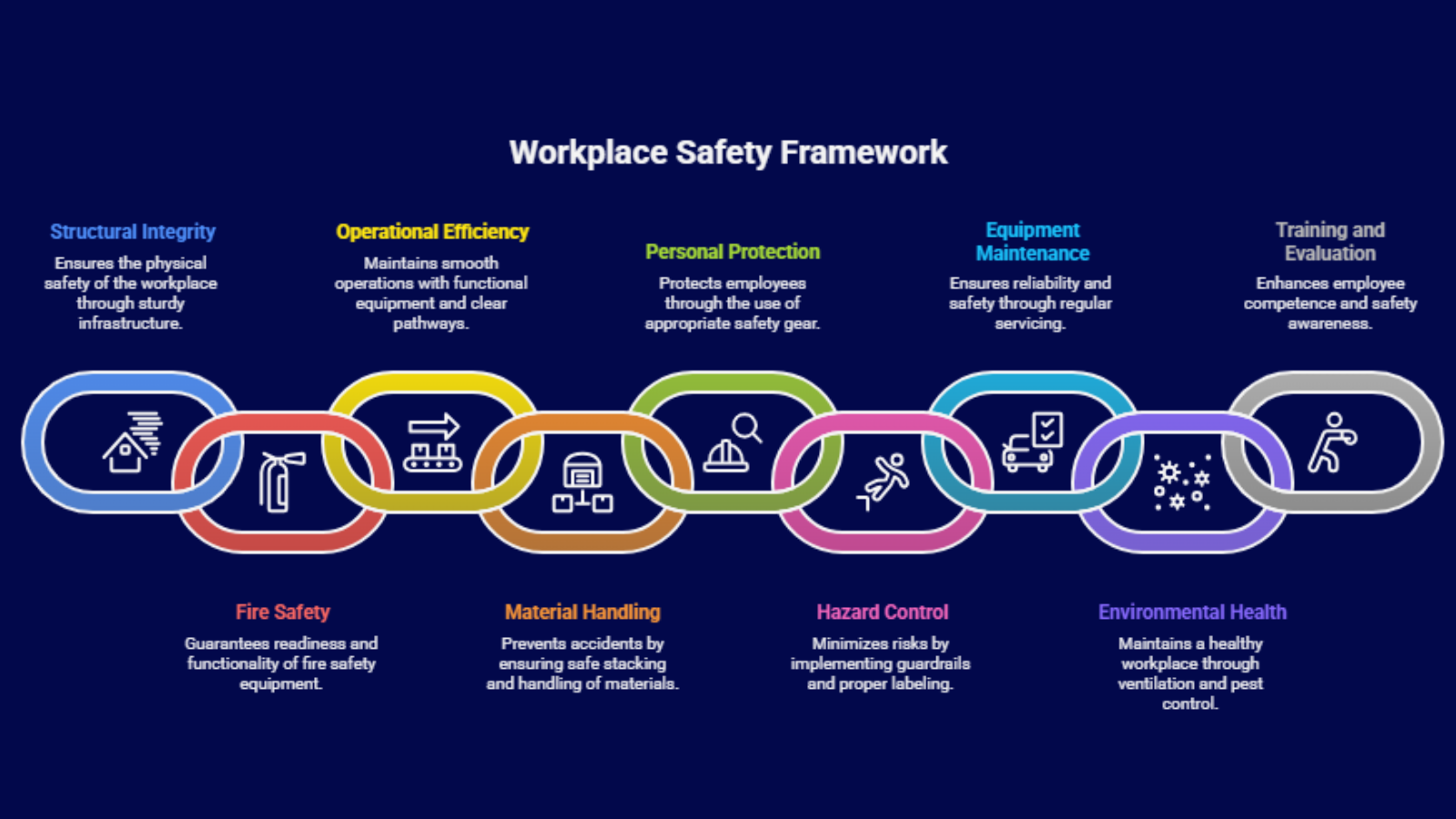

For small warehouse teams, safety is not just a legal requirement but a business necessity. With fewer people to share responsibilities, each worker’s contribution is vital, and accidents can disrupt the entire operation. A clear warehouse safety checklist helps prevent costly mistakes, protect employees, and keep inventory secure. Below are seven key safety steps with general use cases and practical solutions.

1. Promote General Safety Awareness

Use Case: In a small warehouse, workers often rush to complete multiple tasks in limited time, which leads to oversight of safety protocols.

Solution: Regular training sessions, safety awareness posters, and open discussions ensure employees understand the importance of safety in daily routines. When staff actively recognize hazards, they are more likely to prevent accidents before they occur.

2. Use Safety Equipment Properly

Use Case: Improper handling of forklifts or pallet jacks leads to damaged stock or worker injuries. Small teams cannot afford repeated downtime.

Solution: Provide hands-on training for safe use of equipment, enforce guidelines for machine handling, and place guard rails or anti slip mats in key areas. Proper equipment use reduces the chance of accidents and keeps productivity stable.

3. Remove Potential Hazards

Use Case: Cluttered aisles, spilled liquids, or loose cords create tripping and slipping hazards that put workers at risk.

Solution: Adopt a housekeeping routine where team members share responsibility for clearing hazards. Encourage immediate cleanups and provide accessible cleaning supplies. Keeping pathways clear ensures smooth movement of goods and people, reducing workplace incidents.

4. Mark Hazardous Zones

Use Case: Without proper signage, new employees or visitors can unknowingly enter restricted areas such as loading docks or chemical storage sections.

Solution: Use bright safety signs, floor markings, and color codes to highlight danger zones and emergency exits. Clear labeling improves navigation, reduces confusion, and minimizes the risk of accidents.

5. Wear Protective Gear

Use Case: Workers handling heavy boxes or sharp tools may skip wearing gloves or helmets to save time, increasing the likelihood of injuries.

Solution: Make personal protective equipment mandatory, with items like helmets, gloves, and safety vests easily available. Regular reminders and replacing worn gear ensure consistent use and reduce injury risks.

6. Conduct Fire Safety Drills

Use Case: In emergencies, untrained staff may panic or block exit routes, slowing down evacuation.

Solution: Organize regular fire drills to familiarize employees with evacuation procedures. Test alarms, extinguishers, and emergency lights to ensure functionality. Drills prepare teams to respond calmly and effectively in real situations.

7. Perform Regular Inspections

Use Case: Small teams juggling multiple tasks often overlook routine checks, leading to unnoticed issues like faulty racks or malfunctioning equipment.

Solution: Schedule regular and surprise inspections covering racks, equipment, lighting, and emergency systems. Early detection of problems prevents accidents and helps maintain compliance with safety standards.

How to Conduct Warehouse Inspections?

For many small warehouse teams, the idea of conducting a full inspection can feel overwhelming. With limited staff and a long list of operational priorities, safety checks are often pushed aside. Yet inspections are one of the most powerful ways to prevent accidents, avoid losses, and maintain compliance. Breaking the process into clear steps makes inspections manageable and ensures no critical area is overlooked.

1. Examine the Warehouse

The first step is to perform a detailed walkthrough of the warehouse. This involves checking for hazards such as faulty lighting, cracked flooring, damaged storage racks, or blocked emergency exits. Even simple issues like cluttered aisles or misplaced tools can create risks. For small teams, where every worker is essential, identifying and addressing hazards early can prevent disruptions that might otherwise halt operations.

2. Review Safety Programs

Once the physical space has been examined, it is important to compare current practices with recognized standards. Guidelines from OSHA and international safety bodies provide benchmarks for best practices. Reviewing your warehouse against these standards helps identify both strengths and weaknesses. Strong practices should be maintained and replicated, while gaps must be acknowledged openly. For small businesses, this process ensures readiness for audits from regulators or marketplace partners, protecting both reputation and business continuity.

3. Develop Action Plans

Spotting issues is not enough. The next step is to create a structured action plan to address them. A written plan with timelines and responsibilities helps management and staff stay accountable. For example, if broken lighting is identified, the plan should clearly state when it will be fixed and who is responsible. By acting quickly, minor hazards are prevented from escalating into major accidents. This also ensures that subsequent inspections run more smoothly and continuously improve safety standards.

4. Go Beyond Basics

Meeting minimum legal requirements is a good start, but it should not be the end goal. Warehouses that go beyond basic safety protocols foster a stronger culture of responsibility and trust. For small teams, this culture is especially valuable because it boosts morale and creates a sense of shared accountability. Employees who see that management invests in extra precautions feel valued and are more likely to take safety seriously.

What to Include in a Small Team Warehouse Safety Checklist

Final Thoughts

For small teams, every individual plays a vital role in keeping operations smooth and safe. A warehouse safety checklist is more than a compliance tool, it is a framework that minimizes risks, protects employees, and preserves valuable inventory. By following structured safety practices, small sellers can avoid costly disruptions and maintain customer trust.

This process becomes even more efficient with Base.com, which allows sellers to digitize inspections, assign corrective actions, and track progress in real time. Instead of relying on paper checklists or ad hoc routines, Base.com ensures consistency and accountability. For small teams where resources are limited, the platform turns safety from a manual burden into a streamlined process that directly supports growth, efficiency, and long term business continuity.

Click here to know how to know more about the right courier partner as a small brand.

Frequently Asked Questions

1. What is the 6S checklist for warehouses?

The 6S checklist for warehouses focuses on Sort, Set in Order, Shine, Standardize, Sustain, and Safety. It ensures cleanliness, organization, and accident prevention. By following 6S, warehouses improve efficiency, reduce waste, and create a safer work environment where both employees and inventory are protected.

2. What is the daily 5S checklist for a warehouse?

The daily 5S checklist includes Sort, Set in Order, Shine, Standardize, and Sustain. It helps warehouses stay organized by removing clutter, arranging tools systematically, cleaning work areas, maintaining standards, and ensuring consistency. Daily 5S practices enhance productivity, reduce risks, and maintain operational discipline across the warehouse floor.

3. What are the safety requirements for a warehouse?

Warehouse safety requirements include proper training for staff, use of personal protective equipment, clear aisle space, functional fire extinguishers, marked emergency exits, safe storage of hazardous materials, and regular equipment checks. Meeting these requirements ensures compliance with regulations, reduces workplace accidents, and promotes a culture of responsibility.

4. What is a checklist in a warehouse?

A warehouse checklist is a structured tool used to verify safety, cleanliness, and operational readiness. It covers areas such as aisles, racks, equipment, lighting, fire safety, ventilation, and employee training. Using a checklist helps maintain consistency, ensures compliance, prevents accidents, and supports smooth day-to-day warehouse operations.