The digital commerce landscape in India is defined by hyper-growth, a diverse customer base, and intense competition. For Indian Direct-to-Consumer (D2C) brands and marketplace sellers, the key to scaling sustainably lies not just in front-end visibility, but in the flawless execution of their back-end operations.

The complexity of managing inventory across multiple marketplaces like Amazon and Flipkart, handling diverse product data, and ensuring rapid, accurate fulfillment has made siloed systems obsolete. The modern imperative is to adopt an integrated trinity of software: the Order Management System (OMS), Product Information Management (PIM), and Warehouse Management System (WMS).

This holistic approach, which forms the bedrock of modern integrated e-commerce software, transforms operational friction into a seamless flow, directly impacting the bottom line and maximizing e-commerce ROI.

What is the Integrated Trinity of E-commerce Software?

The Integrated Trinity of E-commerce Software refers to the synergistic combination of three core back-end systems: the Product Information Management (PIM), the Order Management System (OMS), and the Warehouse Management System (WMS).This unified architecture serves as the central nervous system of an e-commerce business, synchronizing product data, sales orders, and physical inventory in real time to maximize operational efficiency and reduce costs.

Order Management System (OMS)

The OMS serves as the central brain for all sales transactions. It aggregates orders from every sales channel, your D2C website, mobile app, and all marketplaces into a single interface.

- Core Function: Orchestrates the order lifecycle from receipt to delivery, including payment processing, inventory allocation, and tracking.

- Key Contribution to Integration: Acts as the primary synchroniser, relaying real-time stock commitment data to the PIM and routing fulfilled order information to the WMS.

Product Information Management (PIM)

The PIM is the single source of truth for all product-related data. In the diverse Indian market, where a single product may need multiple language descriptions, regional sizing charts, and specific marketplace compliance attributes, the PIM ensures consistency and completeness.

- Core Function: Centralises, standardises, and enriches product data (descriptions, images, pricing, specifications, compliance documents) for publication across all channels.

- Key Contribution to Integration: Supplies rich, accurate, and channel-optimised product content to the OMS for listing and ensures the WMS has correct product dimensions and handling instructions.

Warehouse Management System (WMS)

The WMS is the operational powerhouse, managing the physical movement of inventory within one or multiple fulfillment centres. This is especially vital for the logistics-heavy Indian e-commerce scene.

- Core Function: Optimises all warehouse processes, including receiving, putaway, storage, cycle counting, picking, packing, and shipping.

- Key Contribution to Integration: Provides real-time, ground-level inventory data back to the OMS, ensuring the system never oversells, and uses the OMS’s optimal routing logic to execute the fastest, most cost-effective fulfillment.

How Does a Unified OMS, PIM, and WMS Architecture Reduce Operational Costs?

For Indian sellers, unifying OMS, PIM, and WMS eliminates significant operational waste by guaranteeing data consistency. This system, for example, prevents costly overselling by using real-time stock from the WMS to update all marketplace listings via the OMS, and minimizes returns by ensuring the PIM’s accurate product details are consistent everywhere. Furthermore, the automation of order routing and label generation through the OMS/WMS synergy drastically cuts down manual labour and secures the lowest-cost carrier for every shipment, collectively maximizing profit margins.

How Does Centralised Data Management Eliminate Errors and Reduce Rework Costs?

Inventory is often the largest capital sink for an e-commerce business; inefficient management can tie up working capital in slow-moving stock or result in lost sales due to stockouts. An integrated WMS tracks the precise location and status of every unit and instantly communicates this information to the OMS. This real-time visibility allows for an “available-to-promise” (ATP) model, optimizing stock levels across multiple fulfillment locations.

- Elimination of Data Silos: When systems operate independently, data entry is often manual and duplicated across spreadsheets, marketplace backends, and local software. A unified system eliminates this. The PIM publishes content, the OMS manages sales, and the WMS handles stock, all feeding into one central data model.

- Pointer: Reduces human errors in pricing, inventory quantity, and product description by over 85%.

- Preventing Costly Overselling (Stock-Outs): In a fragmented system, an order might commit stock that was recently sold on another platform but not yet updated in all channels.

- The Integrated Solution: The OMS receives a real-time ‘available-to-promise’ (ATP) figure from the WMS the instant an order is placed. This instant synchronization ensures that once stock is committed for an order, it is immediately deducted across all selling channels, eliminating cancellations due to overselling a critical factor in maintaining high seller ratings and avoiding marketplace penalties in India.

- Reduced Returns and RTO (Return to Origin) Costs: Product information inaccuracies are a leading cause of customer returns.

- PIM’s Role: By ensuring consistent, rich, and accurate product data (correct dimensions, material, or fit details) is pushed to all channels, the PIM dramatically lowers the rate of product-related returns, directly cutting down on logistics and reverse logistics costs. The high RTO rates in India, especially for COD orders, are mitigated when product confidence is high.

Can Integrated Systems Improve Inventory Management and Lower Holding Costs?

In a high-volume market like India, the speed of fulfillment often determines customer satisfaction and repeat business. Automation, driven by the OMS and WMS synergy, removes bottlenecks that typically slow down the pick, pack, and ship process. The OMS automatically applies the best routing logic to an order, while the WMS directs staff with precision-guided instructions.

- Real-Time, Accurate Inventory Visibility: The WMS tracks every physical movement from receiving to putaway to picking providing the OMS with a single, trustworthy view of stock across all warehouses and fulfillment nodes.

- Benefit: Moves away from conservative, buffer-heavy inventory planning, allowing sellers to maintain lean stock levels (Just-in-Time models), which significantly lowers capital locked in inventory and reduces warehousing and insurance costs.

- Optimised Warehouse Utilisation (WMS Automation): The WMS directs optimal putaway locations and picking routes. This is particularly crucial in high-density Indian warehouses where space is at a premium.

- Cost Reduction: Better space utilisation means delaying the need for expansion, and optimised picking paths mean faster fulfillment with less labour time, translating directly into reduced per-order operational expenditure.

- Centralised Demand Forecasting Data: The combined data from the OMS (sales velocity across all channels) and WMS (stock movement and aging) provides a powerful dataset for predictive analytics.

- Outcome: More accurate purchasing decisions, avoiding both expensive stockouts and overstocking of slow-moving inventory, thereby optimising working capital.

How Does Automation in Fulfillment Lead to Labour and Logistics Savings?

In the fast-paced e-commerce environment, especially when launching seasonal collections or new product lines, speed-to-market is a critical competitive advantage. A PIM-centric approach ensures that a product’s content, including descriptions, images, and necessary marketplace attributes is created once and then instantly syndicated across all D2C and marketplace channels. This automation bypasses the time-consuming process of manual data uploads.

- Automated Order Routing (OMS Functionality): The OMS automatically routes an incoming order to the best fulfillment location (warehouse or dark store) based on predefined logic, such as:

- Proximity to the customer (for faster, cheaper shipping).

- Stock availability and age.

- Carrier performance and cost for that pin code.

- Savings: Reduces manual decision-making time and guarantees the lowest-cost shipping option is chosen for every single order, driving down overall logistics expenditure.

- WMS-Driven Picking Efficiency: Integrated WMS systems enable advanced picking methodologies (batch picking, zone picking, wave picking) using mobile scanners or voice-guided systems.

- Efficiency Gain: Minimises travel time for warehouse staff, accelerating the pick-to-pack process. An average warehouse sees efficiency gains of 20-40% in picking speed.

- Automated Shipping Label Generation: The integrated OMS/WMS automatically selects the correct carrier, calculates the tariff, and generates the compliant shipping label and manifest, including GST-compliant e-invoices, without any manual intervention.

- Impact: Eliminates delays, ensures compliance with diverse Indian logistics partner requirements, and speeds up dispatch time, a key metric for marketplace performance.

Click Here, to read more about why high-growth brands need a scalable Order Management System (OMS)?

How Do Integrated Systems Drive Efficiency and E-commerce ROI?

By providing real-time data flow between product information (PIM), sales orders (OMS), and physical inventory (WMS), integrated systems drastically cut labor costs, prevent overselling losses, and accelerate fulfillment, directly boosting overall E-commerce ROI and customer retention.

How Does a PIM-Centric Approach Accelerate Time-to-Market (TTM)?

Customer loyalty is not just about a great product; it is about a consistent, reliable, and swift end-to-end experience. When PIM, OMS, and WMS operate as a unified system, they deliver direct customer benefits: they keep product pages accurate, maintain correct stock levels to prevent cancellations, and enable fast delivery by optimally routing and executing fulfillment. This transparency minimizes friction points.

- Rapid Product Onboarding: The PIM allows product teams to upload and enrich product data (including multiple high-resolution images, videos, and regional translations) once. This master data is instantly available to all channels.

- Efficiency: Instead of spending days formatting spreadsheets for Amazon, Flipkart, and the D2C website separately, a new collection can be launched simultaneously across all platforms in a fraction of the time. This faster TTM ensures Indian sellers capture early demand and seasonal sales peaks.

- Channel-Specific Content Syndication: The PIM manages different variations of content required by each platform (e.g., character limits for product titles on one marketplace vs. rich media requirements for the D2C site).

- Benefit: Ensures that product listings are always complete and optimised for high conversion on every channel, significantly boosting the e-commerce ROI from content investment.

How Does Unification Enhance Customer Experience and Loyalty?

The future of retail in India is omnichannel, blending online sales with physical fulfillment points like stores or dark warehouses. Unified systems handle this complexity by treating all inventory, whether in a central warehouse or a high-street store as a single pool. The OMS intelligently routes orders based on the customer’s proximity to any stock location, enabling complex fulfillment strategies.

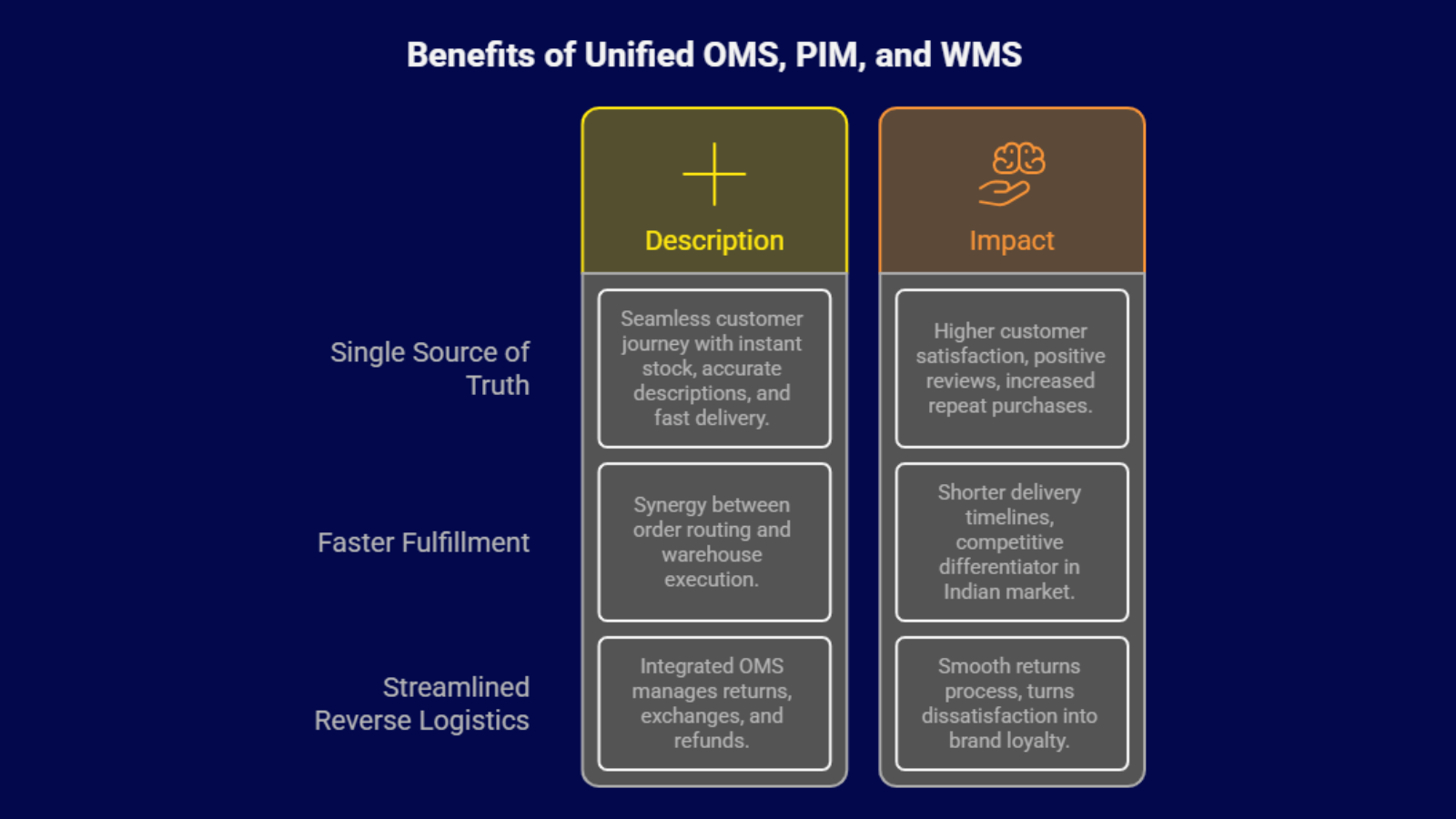

- Single Source of Truth (SSOT) for the Customer: When OMS, PIM, and WMS are unified, the customer journey is seamless:

- The website displays stock instantly (OMS-WMS sync).

- The product description is accurate (PIM).

- The delivery is fast and trackable (OMS-WMS routing and fulfillment).

- Faster and More Accurate Fulfillment: The synergy between optimal order routing (OMS) and efficient warehouse execution (WMS) translates directly into shorter delivery timelines.

- Impact: In the Indian market, where delivery speed is a major competitive differentiator, this leads to higher customer satisfaction, positive reviews, and a significant increase in repeat purchase rates, which is the ultimate e-commerce ROI metric.

- Streamlined Reverse Logistics: The integrated OMS manages the entire return, exchange, or refund process. When a return is initiated, the WMS is automatically notified for physical receipt and quality check, and the PIM/OMS updates the inventory status.

- Efficiency: This structured, automated process makes returns a smooth experience for the customer, turning a potential moment of dissatisfaction into a point of brand loyalty.

Can Unified Systems Better Support Omnichannel and Scale in the Indian Market?

Unified systems are crucial for omnichannel success in the Indian market. They treat all inventory (warehouse, store) as a single pool, allowing the OMS to intelligently route orders for ‘Click-and-Collect’ or ‘Ship-from-Store,’ which is essential for fast, localized fulfillment and scalable growth across physical and digital channels.

- Omnichannel Fulfillment Flexibility: A unified system is essential for modern omnichannel strategies popular with Indian D2C brands, such as:

- Click-and-Collect (BOPIS): Orders placed online are fulfilled from a local store’s inventory (tracked by the WMS/OMS).

- Ship-from-Store: The OMS routes online orders to the nearest physical store for fulfillment, leveraging store inventory to reduce last-mile costs and delivery time.

- Effortless Scalability: As an Indian seller grows from one warehouse to five, or from one sales channel to ten, the integrated system scales naturally.

- Process: Adding a new warehouse simply means integrating a new location into the WMS, which the OMS immediately incorporates into its smart routing logic. Adding a new marketplace is just a connection within the PIM/OMS layer. This eliminates the massive technological debt and costly re-platforming cycles that plague companies using non-integrated, fragmented tools.

The future of profitable e-commerce for Indian sellers hinges on unifying their digital and physical operations. By adopting the integrated power of OMS, PIM, and WMS, businesses move beyond simply surviving the competitive market to establishing a foundation of operational excellence that delivers superior e-commerce ROI.

Discover how to unify your commerce operations and scale your business with confidence at base.com.

Frequently Asked Questions (FAQs)

1. Why should an Indian D2C brand prioritise PIM integration over a simple Excel sheet?

A. For a growing Indian D2C brand, a simple Excel sheet becomes unmanageable as soon as you sell on more than two channels and exceed a few hundred SKUs. PIM centralises and standardises your product data including regional variations, high-resolution media, and marketplace-specific templates making it instantly publishable across all channels. This eliminates the manual effort, reduces product errors that lead to returns, and accelerates time-to-market, which is impossible to achieve with a disconnected spreadsheet.

2. How does warehouse automation software specifically benefit sellers dealing with peak season sales in India?

A. Peak season sales, such as the Great Indian Festival and Big Billion Days, multiply order volumes by up to 10X. During these periods, manual processes fail. Warehouse automation software, part of an integrated WMS, uses logic to manage the surge. It automates order allocation, directs efficient batch picking, and speeds up the packing process through mobile scanning and automated label generation. This efficiency ensures high fulfillment rates, prevents bottlenecking, and allows the seller to manage the volume without exponential increases in temporary labour costs.

3. Is an integrated OMS, PIM, and WMS only suitable for large enterprises in India?

A. No. While traditionally enterprise-only, modern integrated e-commerce software is built modularly and cloud-native, making it accessible to mid-market and high-growth D2C brands in India. The costs of not integrating high labour costs from manual work, losses from overselling, and lost sales from slow TTM quickly outweigh the investment in a unified system, making it a critical step for sustainable scale.

4. What is the most critical metric that improves with an integrated system?

A. The most critical metric is Order Accuracy Rate. The integration ensures that the right product (accurate details from PIM), at the right quantity (real-time stock from WMS), is sent to the right customer (smart routing from OMS). High order accuracy dramatically reduces returns, lowers customer service costs, and builds the trust required for long-term customer loyalty and positive marketplace performance metrics.