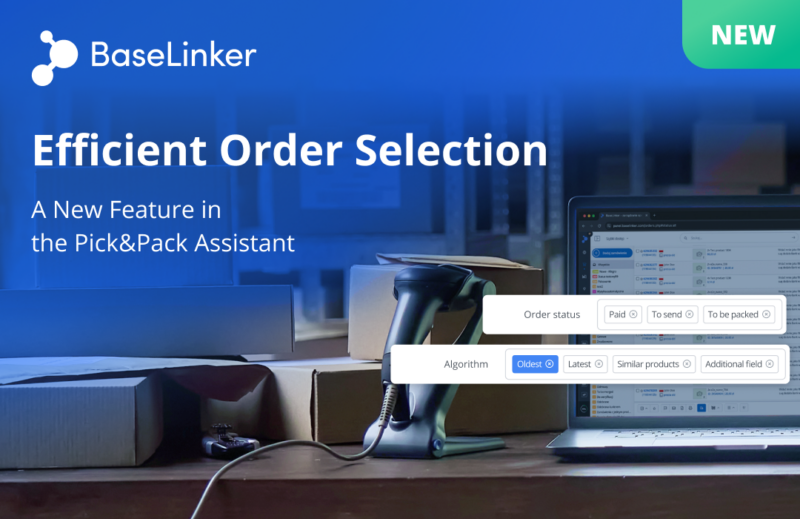

We know that many of you struggle with the efficient picking and packing of orders on a daily basis. Our Pick&Pack Assistant is a key feature that helps manage these warehouse needs. Therefore, we are delighted to introduce a new, enhanced order selection function in the BaseLinker system, which responds to the growing needs of our customers in terms of logistics process management.

Make the warehouse management more efficient with order selection

Order selection is one of the many upcoming features and a step towards bringing BaseLinker closer to a WMS system. The improvement will be particularly noticeable for large sellers who handle hundreds, or even thousands, of orders daily and need advanced solutions for efficient parcel handling. In smaller companies, this new function will also address the needs related to shipment preparation, as well as speed up the packing process. Check out the possibilities for your business!

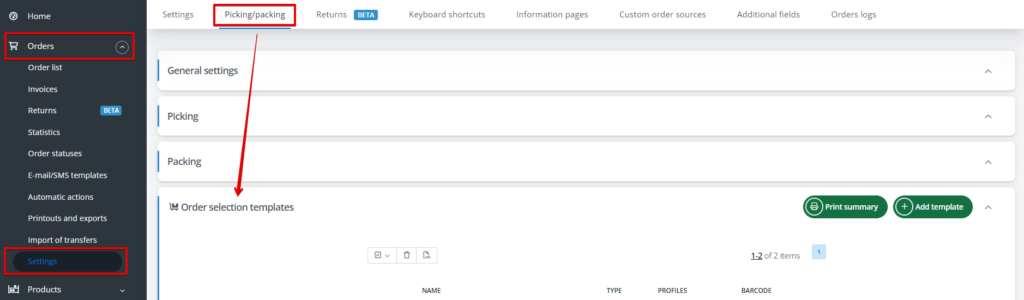

Creating order selection templates

We have noticed that our users create their own, often complicated, systems for picking orders. They are based on many statuses, divided by employees, shipping methods, order sources, or warehouse locations. Our new order selection templates are designed to simplify this process as much as possible. It reduces the need to create multiple statuses or complex automatic actions, and thus also the amount of manual work that may lead to errors.

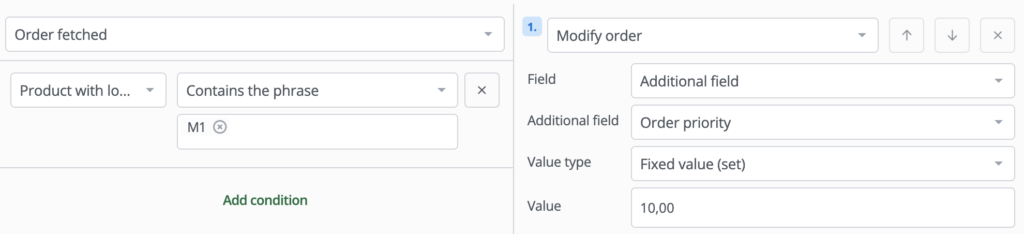

Create several picking templates and optimize the order packing process, taking into account factors such as employees, the number of products in the order, shipping method or order statuses. The process can be personalized using automatic actions – choose which conditions will affect the packing order.

Additionally, you have the possibility of operating simultaneously on many different settings corresponding to packing strategy, making it easy to control the entire process.

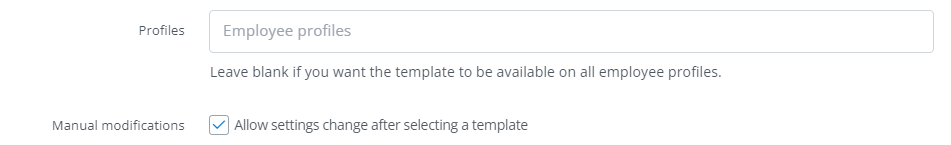

Division into Employee Profiles

Order selection templates can now be assigned to specific employees, as well as blocked from manual modifications. This provides the opportunity to strictly manage the work priorities of pickers and packers, ensuring that each order is prepared for dispatch in the best possible way and that the process is not disrupted by someone without the appropriate authorization permissions.

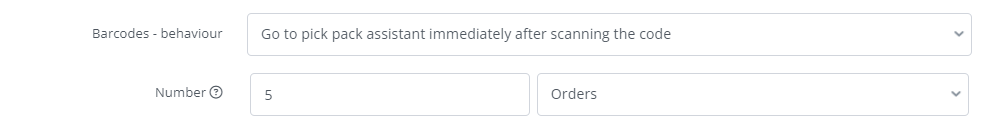

Barcodes

Barcodes play a key role in the modern e-commerce management system, as they minimize the need to use a traditional mouse or keyboard in favor of a barcode scanner, which is a much more convenient tool when it comes to warehouse work. Each template in the BaseLinker system has its barcode. When scanned, the packer receives a list of the next products or orders to pick. Depending on the assigned permissions, a template window may also be displayed, allowing for its quick modification. Thanks to this solution, warehouse employees reduce the number of interactions with the computer screen, which speeds up the entire process and decreases the risk of errors.

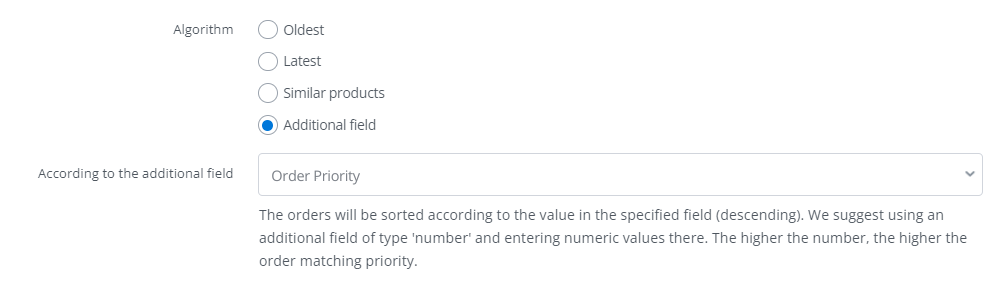

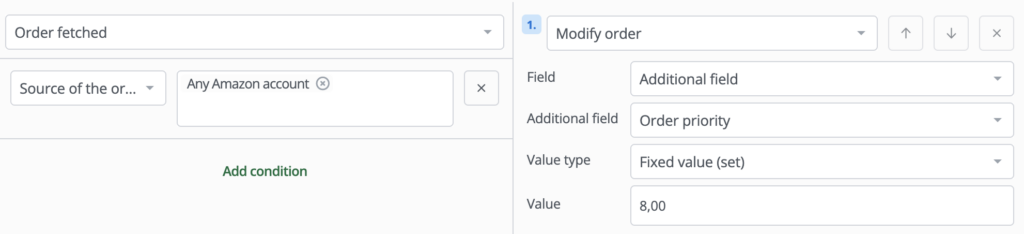

New Selection Method – Additional Field

Another improvement is setting priorities. In addition to options based on order date or product similarity, we added the possibility to create an algorithm based on data entered in an additional field. Create a numerical additional field named “Selection Priority” and fill it with appropriate values (using automatic actions) based on the data in the order. This way, you can precisely determine the picking priority based on selected criteria. As a result, it is possible to manage the order of picking and adapt the process to dynamically changing needs. Examples of conditions:

- Product with location,

- Product with SKU / EAN,

- Order source,

- Shipping time,

- Allegro attributes.

Other Order Selection Settings

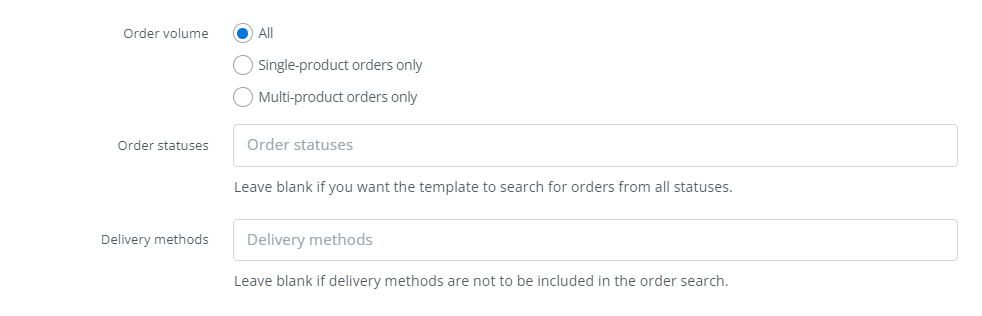

The last three selection criteria focus on the size, status of orders and the method of delivery:

- Order Volume – choose between orders containing one product and multi-product orders. This is particularly important as orders with a single product often have priority in warehouses due to their simplicity and quicker preparation for shipping.

- Order Statuses – unlike previous versions of selection settings, where only one status could be chosen, BaseLinker now offers the possibility to select many different order statuses. This makes it easier to manage and organize the workflow, allowing for more flexible adjustments to the current needs of the warehouse.

- Delivery Methods – involves indicating specific delivery methods as a condition for selecting orders. This allows you to better manage the packing sequence to accommodate the pick-up schedules of different couriers.

Set-up and the process of calling up order selection templates are described in detail in our knowledge base: Pick & Pack Assistant – order selection.

Why Use Order Selection in BaseLinker?

✓ Full Customization – selection templates allow for customizing the picking and packing process according to business needs

✓ Improved Safety – limiting the visibility of templates to different employee profiles allows the process to be better tailored to different job roles and competencies within the company.

✓ Error Reduction – advanced options for choosing a selection algorithm (e.g., based on the oldest/newest orders, similar products, etc.) allow for more efficient order picking and reduced errors.

✓ Increased Productivity and Time Saving – automating the selection process with barcode scanners not only increases productivity but also significantly speeds up the work of the picker and packer.

We hope that this new feature in the BaseLinker system will open up new possibilities for you and help optimize your warehouse processes. We look forward to your feedback! If you have ideas for other improvements to the system, we invite you to leave suggestions in our forum.