Every order that leaves a seller’s warehouse carries more than just the product, it carries the customer’s first impression of the brand. In India’s fast-growing e-commerce market, packaging is no longer just protection; it directly affects shipping costs, return rates, and brand reputation.

Sellers on Amazon, Flipkart, Myntra, and Meesho often face losses due to packaging errors. For example, Amazon penalises sellers with higher FBA fees when oversized boxes increase dimensional weight charges. Flipkart sellers frequently deal with higher RTOs when fragile goods are poorly packed, causing damages in transit. Myntra’s fashion sellers are pushed to maintain premium packaging standards because poor packaging leads to negative reviews and lower seller ratings, reducing visibility during events like the Big Fashion Festival. Similarly, Meesho sellers, who often operate on slim margins, risk profitability when overuse of fillers or heavy cartons drives up courier bills. Avoiding such mistakes is crucial for long-term growth.

Here are the top 5 packaging mistakes Indian sellers make, and strategies to fix them.

Mistake 1: Using Oversized Boxes

Many Indian sellers, especially in categories like cosmetics, electronics accessories, or home decor, make the common mistake of packing small products into large cartons “just to be safe.” While the intention is to avoid damage, this approach backfires because shipping partners such as Blue Dart, FedEx, Delhivery, and Ecom Express charge sellers based on dimensional weight (DIM weight) rather than actual product weight. This means you end up paying for empty space inside the carton, significantly increasing freight costs.

Fix: Adopt Smart Packaging Practices

To avoid DIM weight penalties and wasted costs:

- Use right-sized corrugated boxes tailored to the product’s dimensions.

- Switch to custom polybags or padded mailers for lightweight, non-fragile products.

- Leverage packaging advisory from logistics providers like Delhivery, XpressBees, or Shiprocket who guide sellers on cost-effective solutions.

- Standardise packaging across SKUs to reduce material waste and streamline fulfilment.

- Regularly review courier invoices to identify DIM penalties and redesign packaging accordingly.

By investing in optimized packaging, sellers not only reduce shipping costs but also improve warehouse efficiency, minimize void fill, and deliver a better unboxing experience to customers.

Mistake 2: Overuse of Cushioning and Fillers

Many sellers believe that adding excessive layers of bubble wrap, foam sheets, or even newspapers is the safest way to protect fragile products. While this may reduce the chances of damage, it creates another major problem – higher shipping weight and inflated packaging costs. Courier partners like DTDC, Blue Dart, and XpressBees calculate freight charges based on weight slabs. Unnecessary fillers not only increase costs but also generate more waste, leading to poor sustainability scores.

Fix: Smarter Protective Packaging Solutions

To reduce shipping costs and enhance customer experience:

- Switch to molded pulp trays that offer firm cushioning without excess bulk.

- Use lightweight air pillows instead of heavy bubble wrap.

- Adopt recyclable and eco-friendly fillers like shredded paper or kraft padding.

- Right-size packaging boxes to minimise the void space that requires filling.

- Train packing staff to use protection efficiently, not excessively.

By optimising cushioning, sellers can cut packaging weight, lower shipping bills, and appeal to sustainability-conscious buyers, all while keeping fragile products safe in transit.

Mistake 3: Ignoring Lightweight Packaging Materials

A common mistake among Indian e-commerce sellers is the use of heavy corrugated cartons or double-walled boxes for every product, regardless of its fragility. While strong cartons are essential for breakable items, they are unnecessary for lightweight goods like apparel, stationery, or soft toys. Shipping partners such as XpressBees, Ecom Express, and Delhivery charge sellers based on weight slabs, so every extra gram adds to your logistics bill. Over-packaging not only increases freight costs but also reduces warehouse storage efficiency.

Fix: Smarter, Lightweight Alternatives

To save costs without compromising protection:

- Use poly mailers or kraft paper mailers for soft goods like clothes and fabric items.

- Adopt recyclable envelopes for smaller SKUs that don’t require boxes.

- Reserve heavy corrugated cartons for fragile, bulky, or high-value products.

- Invest in compostable or biodegradable mailers to improve eco-friendliness and brand value.

- Review packaging by product category to avoid a one-size-fits-all approach.

By shifting to lightweight materials, sellers can lower freight charges, speed up packing, and improve sustainability, all while maintaining product safety.

Mistake 4: Non-Compliance with Courier Packaging Guidelines

Courier companies such as DTDC, Blue Dart, and FedEx enforce strict packaging standards to ensure shipments can withstand long-distance handling. When sellers cut corners by using weak cartons, non-standard tape, or irregular box sizes, shipments risk being delayed, rejected, or charged extra handling fees. Non-compliance also increases the likelihood of in-transit damage, leading to costly returns and unhappy customers.

Fix: Stay Aligned with Courier Standards

- Use certified packaging suppliers who meet courier specifications.

- Follow carrier guidelines for box strength, tape type, and labeling.

- Standardise packaging materials across SKUs to simplify compliance.

- Refer to packaging updates from logistics aggregators like Pickrr, Shiprocket, or NimbusPost.

- Train staff on courier requirements to reduce shipment rejections.

By ensuring packaging compliance, sellers can avoid penalties, reduce RTOs, and maintain smooth partnerships with courier networks, especially during high-volume festive periods.

Mistake 5: Treating Packaging Only as a Box, Not a Process

Most Indian sellers see packaging only as “what goes around the product.” But the real hidden cost often lies in the packing process itself. Slow picking, inconsistent box selection, and manual trial-and-error during order spikes delay dispatches and inflate labour costs. For example, if a packer spends even two extra minutes selecting the right carton, across 1,000 orders, that’s more than 33 hours lost in a single day. Such delays not only increase overhead but also reduce the seller’s chances of meeting platform SLAs, leading to lower ratings and fewer sales opportunities.

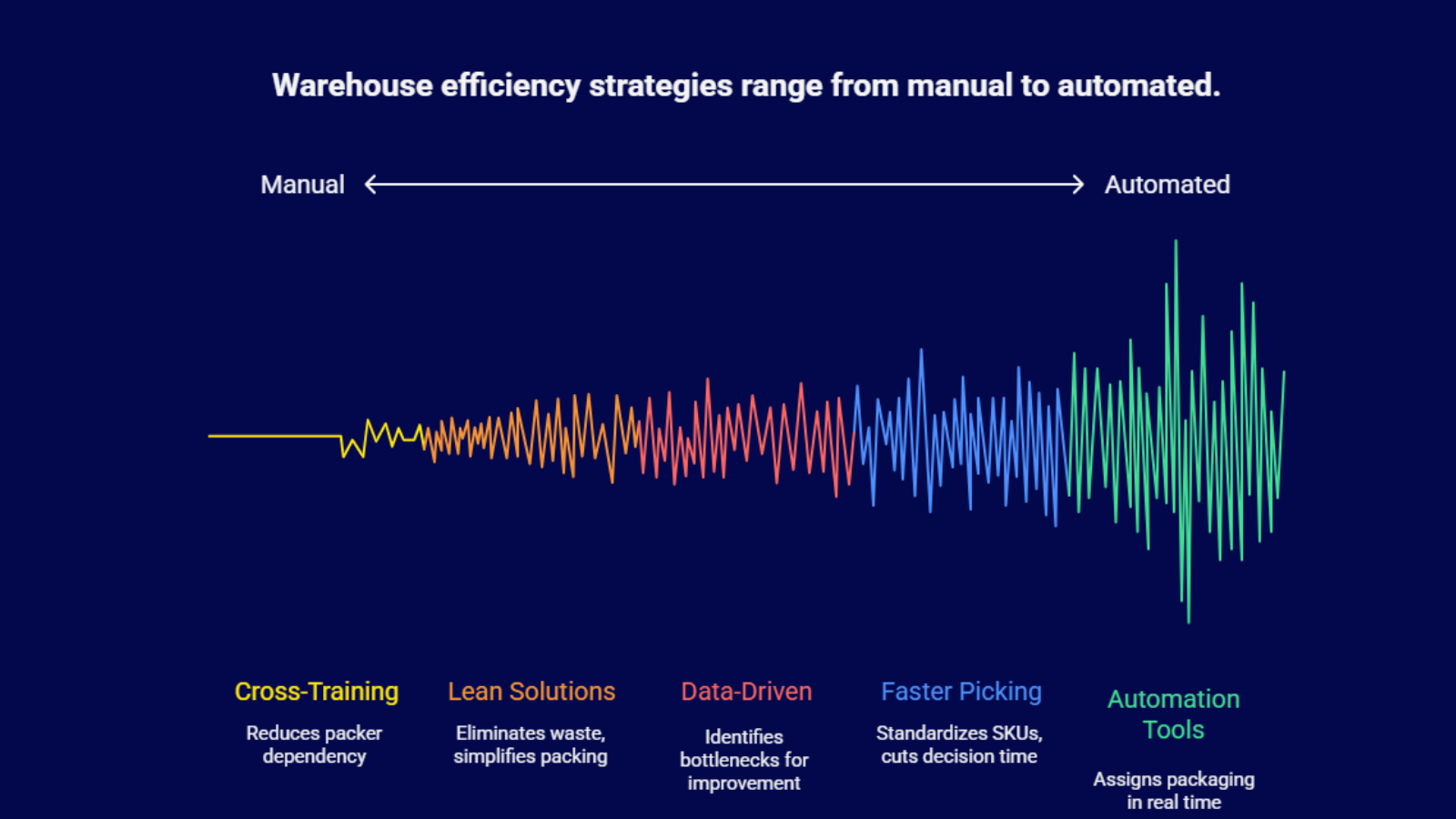

Fix: Optimise Packaging as a Lean Process

To truly cut costs and scale profitably, sellers need to think of packaging as a workflow, not just a material expense:

- Faster Picking & Packing: Standardise SKUs with pre-assigned box sizes or mailers to cut decision-making time.

- Lean Solutions: Introduce 5S/6S lean methods in warehouses to eliminate wasted steps, reduce motion, and simplify packing lines.

- Automation Tools: Use packaging automation systems or software like Base.com to assign the right packaging in real time.

- Data-Driven Improvements: Track average pack-time per order and identify bottlenecks for continuous improvement.

- Cross-Training Staff: Train teams in efficient methods to avoid dependency on a few experienced packers.

By treating packaging as a process to be standardised, measured, and optimised, sellers can save both time and money. The result is faster dispatches, fewer SLA breaches, and a scalable operation ready for peak-season surges.

Bonus Tip: Think Beyond the Box

Most sellers only focus on the cost of the box or filler, but the real cost driver is process inefficiency. Slow manual packing, repeated errors in box selection, and lack of standardisation often add hidden labour costs and delays to order fulfilment. For instance, when a packer spends an extra two minutes choosing the right box during a peak sale, multiplied across thousands of orders, it translates into hours of lost time and missed dispatch windows. Customers notice delays, and platforms like Amazon or Myntra reflect it in lower seller ratings. The real win comes from streamlining the entire packaging process, not just shaving off material costs.

For instance, Kiran Shah, the founder of Go Zero, recently shared a powerful lesson from his ice cream business. His team stored plastic cups in cartons, and cartons in crates for cold chain transport. Each crate carried 5 cartons, but he noticed empty space inside. Instead of ignoring it, he experimented and realised that by reducing each carton’s height by just 2mm, a sixth carton could fit in the crate.

That small 2mm change delivered a 20 percent boost in storage and transport efficiency. Every 100 crates now carried 600 cartons instead of 500, without adding trucks, space, or costs. In just 10 minutes of rethinking “standard” packaging, Go Zero saved over ₹5 lakhs in a single month.

For Indian e-commerce sellers, the lesson is clear: packaging optimization is not just about avoiding DIM weight penalties or using eco-friendly fillers. It is about questioning assumptions, observing small inefficiencies, and making precise adjustments that scale massively.

Final Thoughts

The festive season magnifies every inefficiency. Manual fixes like training staff or buying new packaging materials can only go so far. To scale effectively, sellers need automation and data-driven control. Base.com offers this advantage by standardising packaging decisions, tracking performance, and integrating directly with fulfilment partners. Its Pick-Pack Assistant further strengthens operations by guiding warehouse staff during picking, verifying accuracy at packing, and automating label generation to reduce costly errors.

Together, these tools transform packaging and fulfillment from reactive costs into proactive growth drivers. By automating smarter, sellers not only save on courier charges but also ship faster, reduce returns, and win customer trust. In today’s crowded e-commerce landscape, that edge makes the difference between surviving and leading.

Click here, to learn more about 5 Must-Dos for Fashion Sellers Before the Festive Rush.

Frequently Asked Questions

1. What are the mistakes in packaging design?

Common mistakes include using oversized boxes, over-relying on fillers, ignoring lightweight materials, neglecting courier compliance, and not consolidating shipments. These errors increase shipping costs, waste storage space, and frustrate customers. Poor design can also weaken protection, cause product damage, and hurt brand reputation. Smart, right-sized design is critical for efficiency and profitability.

2. How can packaging affect pricing?

Packaging directly impacts product pricing through shipping, storage, and material costs. Oversized or heavy packaging triggers higher courier fees, while poor design increases returns and replacements. Sustainable, lightweight, and efficient packaging reduces logistics expenses and helps sellers keep product prices competitive while maintaining margins. Good packaging also adds perceived value, supporting premium pricing.

3. What are packaging errors?

Packaging errors are mistakes that occur in selecting, designing, or applying packaging materials. Examples include wrong box sizes, poor cushioning, non-compliance with courier standards, or mislabeling. These errors often lead to product damage, increased costs, delivery delays, and higher return rates, creating inefficiencies in the supply chain and lowering customer satisfaction.

4. How do packaging inefficiencies affect supply chain costs and waste?

Inefficient packaging increases supply chain costs by raising DIM weight charges, adding unnecessary fillers, consuming excess storage, and leading to product damages. These issues create waste in materials, transport space, and reverse logistics. By contrast, optimized packaging reduces costs, improves handling efficiency, lowers returns, and supports sustainability goals, strengthening the overall supply chain.