Indian e-commerce is projected to become one of the largest markets globally, its growth is fueled by increasing internet penetration, rapid digital adoption in Tier-2 and Tier-3 cities, and supportive government policies. However, this explosive growth brings unprecedented operational complexity. As a result, for Indian sellers, the race to market dominance isn’t just about customer acquisition, but rather about executing the most efficient, error-free, and scalable supply chain.

This detailed guide explores the future of e-commerce operations in India and explains how the strategic deployment of a robust Order Management System (OMS) and Warehouse Management System (WMS) is a fundamental requirement for survival and growth.

What are the Current Dynamics and Operational Imperatives of Indian E-Commerce?

The Indian e-commerce ecosystem is characterized by a unique set of challenges and opportunities that demand a specialized operational strategy.

Key Market Dynamics for Indian Sellers

| Parameter | Current Status & Implication for Operations |

| Market Growth | Expected to grow at a high Compound Annual Growth Rate (CAGR), driven by Tier-2/3 demand. Implication: Massive scale-up required. |

| Logistics Complexity | Diverse geography, varied pin-code serviceability, and a high reliance on Cash-on-Delivery (CoD). Implication: Requires intelligent route and payment management. |

| Customer Expectations | High demand for quick commerce (10-60 minute delivery) in metropolitan areas and reliable 2-3 day delivery elsewhere. Implication: Need for decentralized inventory and speed. |

| Returns & Exchanges | High return rates, particularly in fashion and electronics. Implication: Reverse logistics is a critical operational flow. |

| Multichannel Selling | Dominance of major marketplaces (Amazon India, Flipkart) alongside direct-to-consumer (D2C) websites. Implication: Single, unified operational view is essential. |

The future of operations rests on the ability to master this complexity through seamless technology integration.

How will integrated OMS and WMS unify operations and automated real-time inventory execution?

E-commerce operations are moving away from siloed tools one for orders, one for inventory, one for shipping to a single, unified digital platform. This is the inflection point where integrated OMS and WMS become the central nervous system of the business.

The Role of Order Management Systems (OMS)

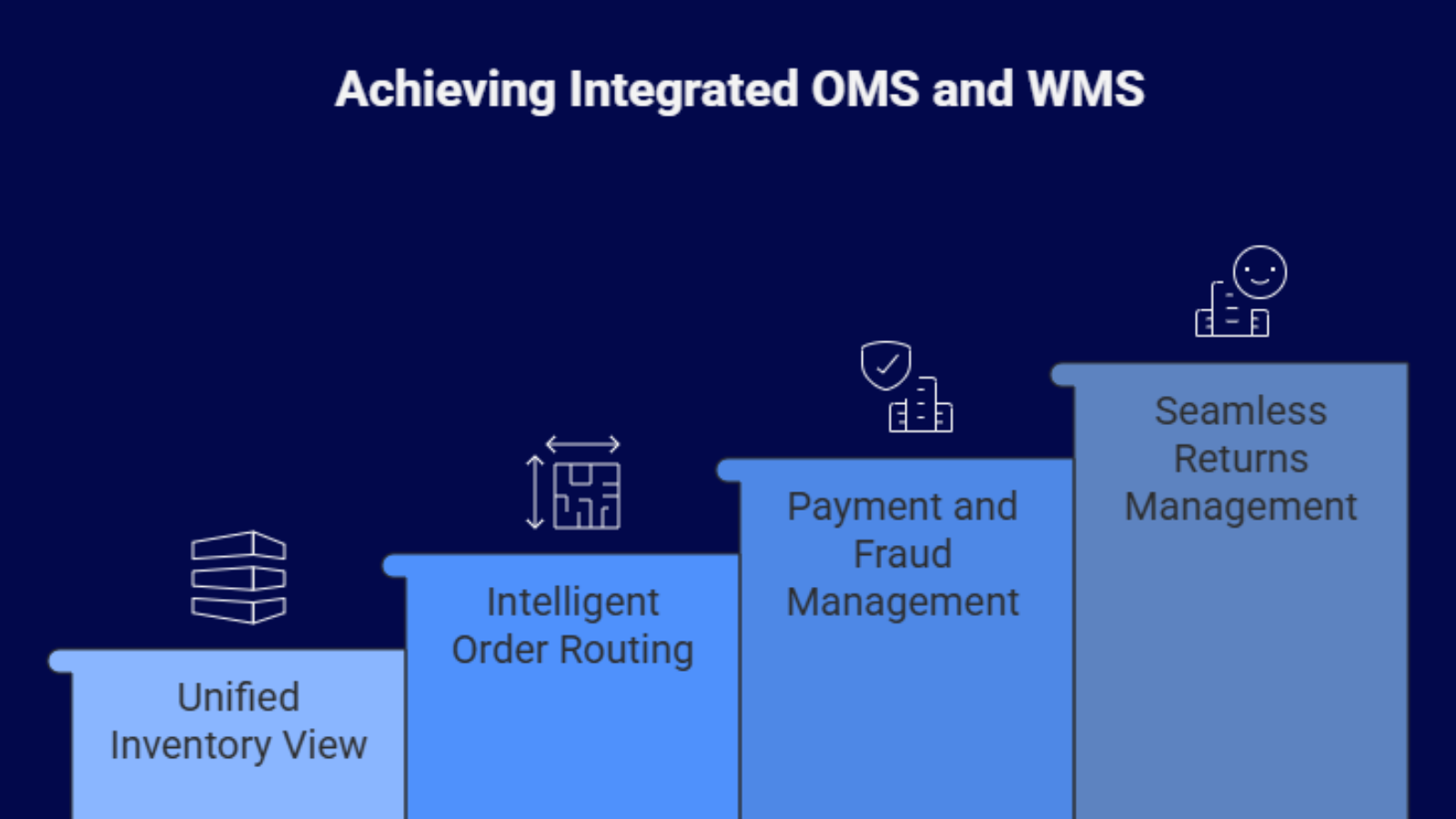

An OMS is the front-end control center for all sales channels. Its future-focused capabilities for Indian sellers include:

- Unified Inventory View (Single Source of Truth): The OMS aggregates inventory data from all warehouses, physical stores, and 3PLs, displaying a real-time, accurate stock level across all sales channels. As a result, this eliminates stockouts on one platform while a product sits idle in another.

- Intelligent Order Routing (IOR): The next generation of OMS uses algorithms to automatically route an order to the most optimal fulfillment location based on pre-set rules. These rules are crucial in India:

- Lowest Shipping Cost: Routes to the nearest, most cost-effective warehouse.

- Fastest Delivery Time: Routes to the location closest to the customer for express delivery.

- Inventory Prioritization: Routes to a warehouse holding old stock to minimize carrying costs.

- Payment and Fraud Management: Given the high CoD prevalence, an advanced OMS integrates with payment gateways and logistics partners to dynamically verify pin codes, manage CoD limits, and flag suspicious orders for review, reducing RTO (Return to Origin) risk.

- Seamless Returns Management: It automates the returns process, instantly generating return labels and initiating refunds only after the WMS confirms the item’s receipt and condition, drastically improving customer experience and retention.

The Role of Warehouse Management Systems (WMS)

The WMS is the back-end execution engine, responsible for managing every physical movement within the warehouse. Its evolution is centered on automation and precision.

- Optimized Putaway and Storage: Utilizing data on sales velocity and size, a modern WMS directs staff on the most efficient location to store incoming goods (putaway). High-velocity items are stored closer to packing stations to minimize travel time (known as slotting optimization).

- Efficient Picking Strategies: It moves beyond paper lists to direct picking using Radio Frequency (RF) handheld scanners or sophisticated technologies like Pick-to-Light or Voice Picking. Strategies include:

- Batch Picking: One picker fulfills multiple orders simultaneously.

- Zone Picking: Pickers are assigned to specific zones, handing off the order to the next zone.

- Labor and Task Management: The WMS monitors the performance of every operator in real-time. It uses dynamic task interleaving, assigning a putaway task immediately following a picking task in the same area to eliminate idle time and maximize labor efficiency, which is vital in a labor-intensive market like India.

- Integration with Automation: The true future lies in the WMS acting as the operational software for physical automation, such as conveyor belts, sortation systems, and Automated Guided Vehicles (AGVs) or Autonomous Mobile Robots (AMRs). The WMS directs these robots to move inventory, turning the warehouse into a fully automated sorting and fulfillment center.

Where the Future lies: OMS+WMS?

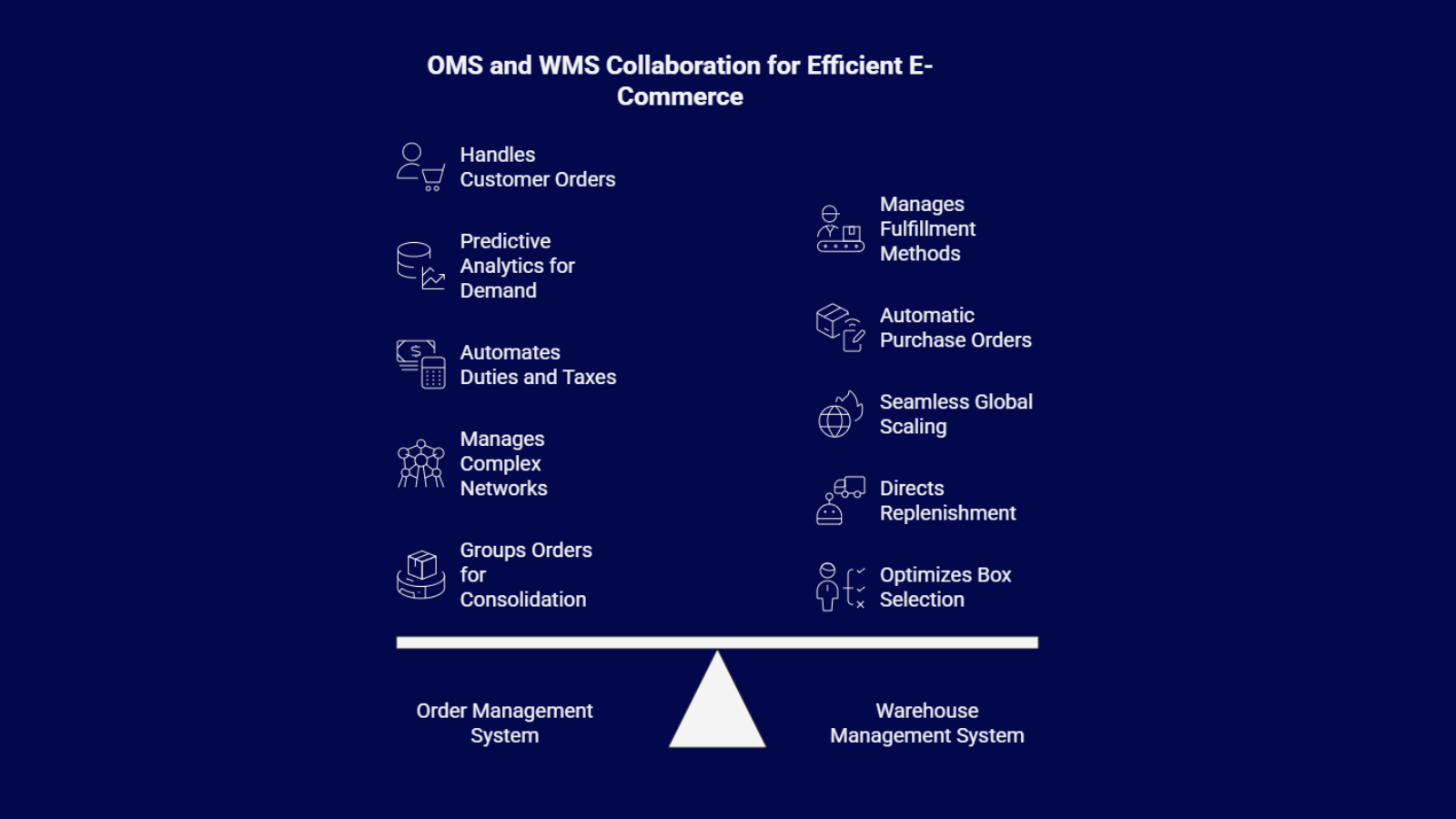

The combined power of an integrated OMS and WMS unlocks hyper-efficiency. The OMS handles the “What” (the customer order, the chosen fulfillment location), and the WMS handles the “How” (the most efficient method to pick, pack, and ship).

Future E-Commerce Operations: Automation & Intelligence

| Operational Area | Automated Future (Driven by OMS/WMS) |

|---|---|

| Inventory Planning | Predictive analytics models in the OMS/WMS use AI to forecast demand by SKU and location, automatically suggesting purchase orders to prevent stockouts. |

| Cross-Border Trade | OMS handles complex duties, taxes, and customs documentation automatically, making it seamless for Indian sellers to scale globally. |

| Distributed Inventory | OMS manages complex networks, including micro-fulfillment centers (MFCs) in city centers for quick commerce, directing replenishment from larger regional hubs (WMS-managed). |

| Sustainable Operations | WMS optimizes box selection to reduce packaging waste, and OMS groups orders for consolidation to reduce the carbon footprint of multiple shipments. |

This synergy translates directly into a higher Customer Lifetime Value (CLV) through reduced delivery errors and faster service, while simultaneously reducing fulfillment costs.

Stop managing complexity. Master it.

The foundation of your e-commerce future is a unified operational platform that scales with the unique demands of the Indian market. Don’t let siloed systems and manual processes stifle your growth.

Discover how a fully integrated OMS and WMS can transform your operations from a cost center into a competitive advantage. Learn more about scalable e-commerce fulfillment and book a free consultation at base.com.

Conclusion

The future of e-commerce operations in India is intrinsically linked to the level of digital sophistication adopted by its sellers. The market is too vast and the competition too fierce for manual, disjointed processes. The strategic implementation of the integrated OMS and WMS, working in tandem, is the only sustainable path to achieving the hyper-efficient, scalable, and customer-centric fulfillment that defines success in the coming decade. By investing in these foundational technologies, Indian sellers can not only keep pace with the market but also set a new global standard for digital commerce execution.

Base.com is an integrated OMS and WMS platform built for modern ecommerce brands. Automate orders, synchronize inventory, and ship faster across every channel.

Frequently Asked Questions (FAQs) for Indian Sellers

Q1: How is OMS different from the dashboard provided by Amazon India or Flipkart?

A1: Marketplaces provide a platform-specific order view. An OMS is a neutral, centralized system that integrates with all sales channels (Amazon, Flipkart, Shopify, Myntra, etc.) and your own warehouses. It provides a single, unified view of inventory and orders across your entire business, enabling cross-channel fulfillment and strategic inventory positioning that marketplace dashboards cannot offer.

Q2: My business uses only an ERP for inventory. Do I still need an OMS and WMS?

A2: Yes. An ERP (Enterprise Resource Planning) is excellent for financial tracking, procurement, and high-level inventory valuation. However, it lacks the execution-level depth of an OMS (order routing, returns management) or a WMS (directed picking, slotting, labor management). In practice a modern e-commerce operation requires the specialized, real-time control provided by OMS/WMS, which then feeds summary data back to the ERP.

Q3: Is the investment in an integrated OMS/WMS justifiable for an MSME (Micro, Small, and Medium Enterprise) seller in India?

A3: Absolutely. While a small seller can start with basic tools, the cost of inefficiency very quickly overtakes the cost of a system. In particular, common costs of inefficiency include high RTO due to slow fulfillment, penalties for late marketplace shipments, and lost sales due to phantom inventory (stockouts). As a result, investing in a modular, cloud-based OMS/WMS solution allows MSMEs to scale operationally without massive upfront capital expenditure, making such an investment especially justifiable once they consistently handle over 500–1,000 orders per month.